Hey Guys,

Scratching my head here,

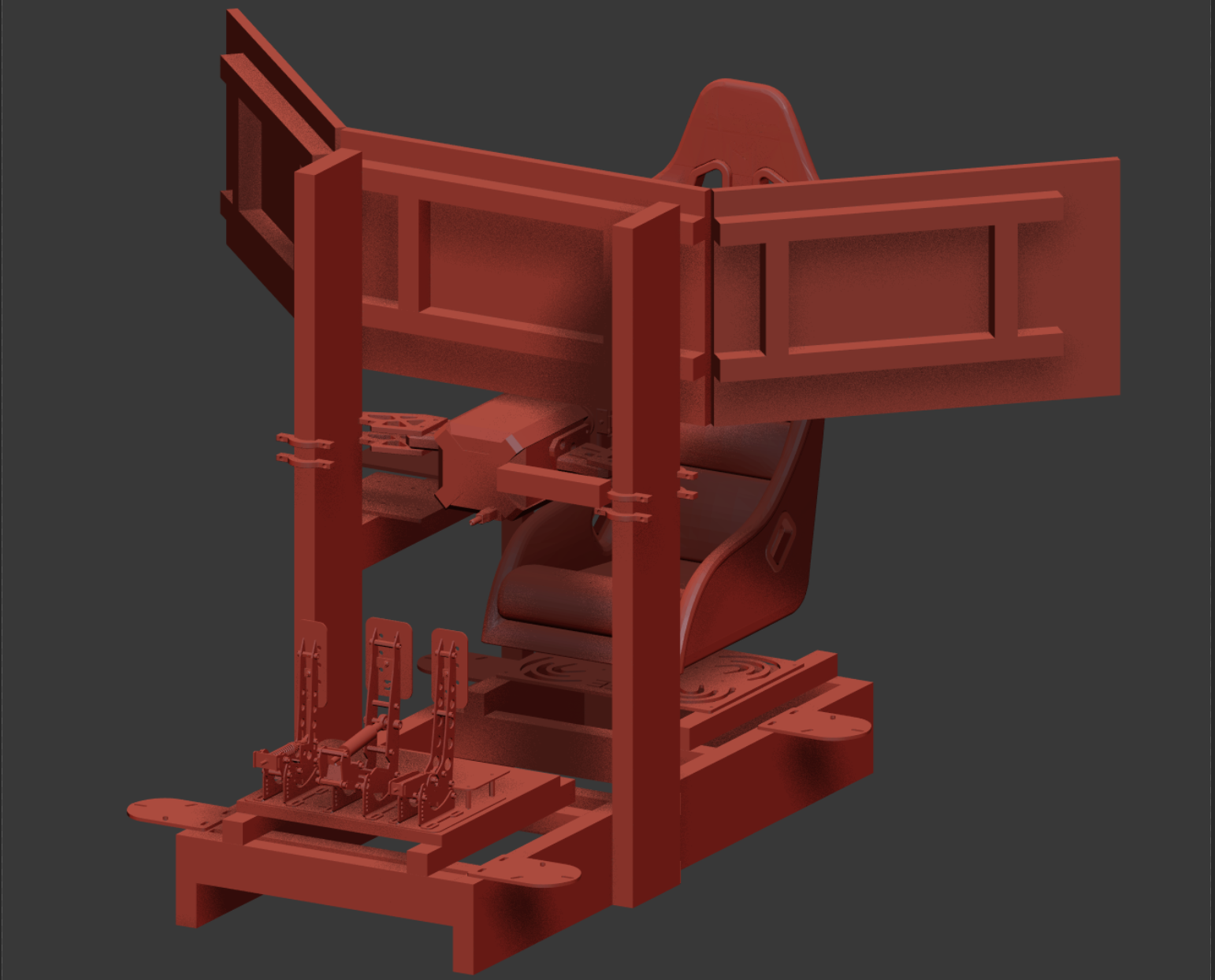

I designed a rig and had it powder coated in which I have yet to build it its still boxed I took out just 1 piece to check it last week,

Here on the back for the screens I had this idea in which yes I have not seen before for mounting screens this method,

but for me looked to be a great idea for mounting them + be adjustable,

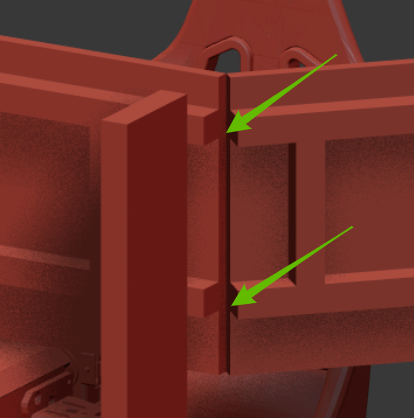

I want to use these on the corners I imagined 2 be ok for 24-27 inch but with them been 32 ultra wide I thought 2 each side would do the trick,

The idea is to use 4 of these 2 each side,

like so,

Problem why I made the thread I am not sure if to tap the holes for the mounts using a taper or thread forming I was reading, anyways I bought a taper set but in my mind I imagined be a M10 max,

looking at the set the M12 seems to be the main one that would tap the threads as of yet I have not ordered all the small brackets and corner pieces the nuts and bolts,

does this want taping with a taper set or would some thread forming bolts make the threads of the Aluminium,

would just rather ask than destroy the parts by learning when you guys have a lot of experience with this stuff,

Just looking at the pattern in the center how the parts are only on the walls for the threading leaves me not much confidence would need to be clamped.

Regards Scott

Scratching my head here,

I designed a rig and had it powder coated in which I have yet to build it its still boxed I took out just 1 piece to check it last week,

Here on the back for the screens I had this idea in which yes I have not seen before for mounting screens this method,

but for me looked to be a great idea for mounting them + be adjustable,

I want to use these on the corners I imagined 2 be ok for 24-27 inch but with them been 32 ultra wide I thought 2 each side would do the trick,

The idea is to use 4 of these 2 each side,

like so,

Problem why I made the thread I am not sure if to tap the holes for the mounts using a taper or thread forming I was reading, anyways I bought a taper set but in my mind I imagined be a M10 max,

looking at the set the M12 seems to be the main one that would tap the threads as of yet I have not ordered all the small brackets and corner pieces the nuts and bolts,

does this want taping with a taper set or would some thread forming bolts make the threads of the Aluminium,

would just rather ask than destroy the parts by learning when you guys have a lot of experience with this stuff,

Just looking at the pattern in the center how the parts are only on the walls for the threading leaves me not much confidence would need to be clamped.

Regards Scott