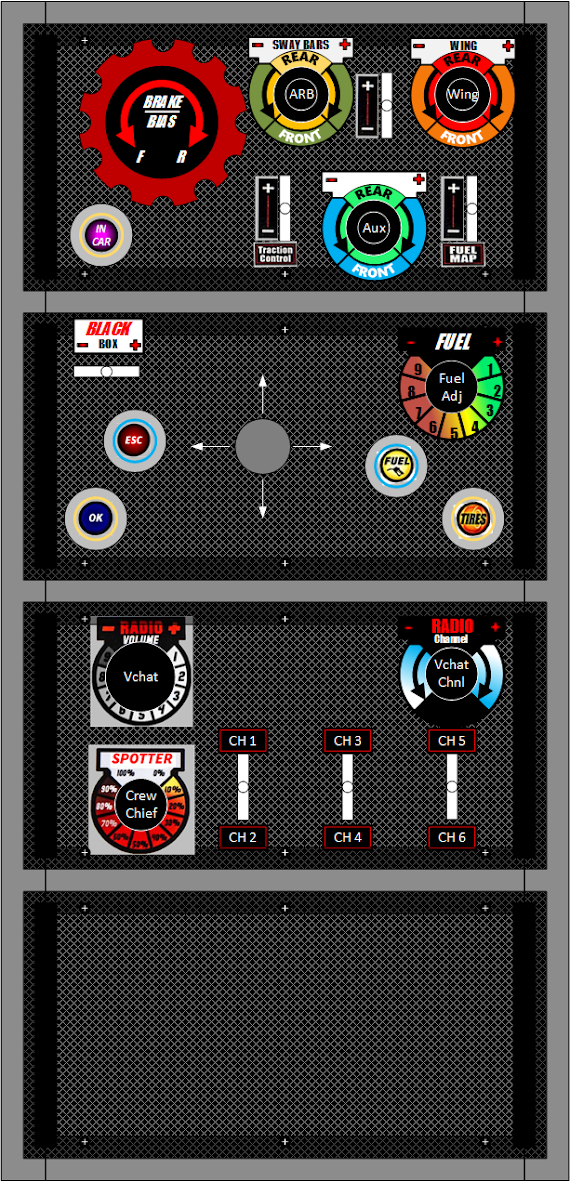

I've finally starting to build this thing in earnest. Below is my sketch layout for the final product. The idea is that its the same general size as the center console in a car, and the plan is for it to be placed in the same general physical location relative to the driver seat/steering wheel. I've laid this out as separate panels, and tried to make every panel layout unique so that there are easy landmarks. Note the bottom panel is blank, as it is down at H-shifter level. But, I'm considering putting some general Simhub adjustments there to be able to tweak the strength of some effects, and Simhub Master volume....while in-car.

I've built up the panels, I cut them out of 1/8" lexan. I have a Bodnar BBI-64 to use as the controller for the whole thing.

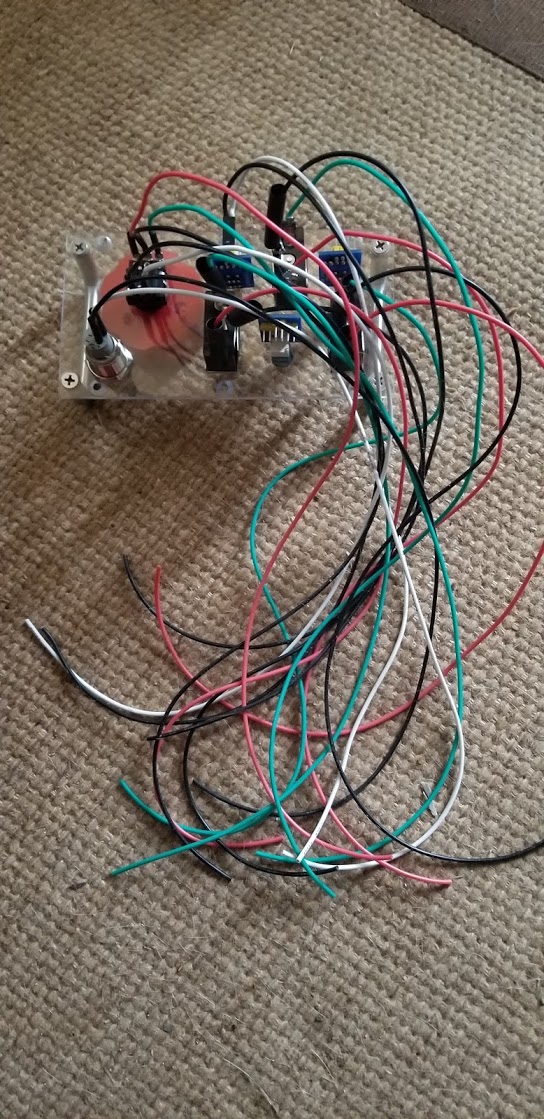

Last night I spent some time soldering leads onto the first panel. My plan is to wire each of these to double row 0.100" headers (see below) in a standard fashion for plugging into the BBI-64. So I bought this kit of crimp-pins and various header sizes:

Dual encoders use 5 inputs (inner L/R, outer L/R, push-button), plus GND wires = 2x5 female header.

Currently this prototype is just wood and hand drilled lexan. I have a roll of Carbon-fiber Vinyl which I intend to use to wrap the whole thing once I'm happy with it. I may have the final panels laser cut after I make any needed refinements.

I've already decided that a couple of things are too close to the side guards (brake bias, and a couple others. So, I'll probably widen the whole thing by 1-2" and respace everything to ensure a minimum clearance between everything.

The larger cockpit build is being done around the ergonomics of my real racecar (a 1990 Spec Miata). I have a spare set of miata pedals that I'm currently instrumenting with a 200 kg loadcell, and potentiometers for clutch/throttle. I also have a spare set of stalks and a ignition key...that I may wire up to another bodnar box.

Parts List

Single axis encoders with push. CTS288V232R161B2. Used for Brake Bias, and volume knobs.

www.digikey.com

www.digikey.com

Dual axis encoders with push. No part# per se, just a web link. Used for sway-bar, and wing adjustments.

www.propwashsim.com

www.propwashsim.com

Joystick, 4 way switch. Again no part #, just ebay listing.

Raised Pushbutton switch (with LED). Ebay listing:

Flush pushbutton (with LED). Ebay listing:

Various knobs. These shaft hole in these knobs were all about 0.010" too small for the CTS288 shaft. I drilled them out with a 1/4" drill bit to fit. Ebay listings:

Brake Bias knob. Apex Sim Racing. I actully bought a different knob (that is 3d printed plastic), but Apex doesn't seem to sell it anymore. The closest is now billet machined (it looks nice, though twice the price):

www.apexsimracing.com

www.apexsimracing.com

Switches. I'm not happy with the action of the switches. So, I won't bother listing those for now. When I decide on a replacement, I'll update this with that part.

I've built up the panels, I cut them out of 1/8" lexan. I have a Bodnar BBI-64 to use as the controller for the whole thing.

Last night I spent some time soldering leads onto the first panel. My plan is to wire each of these to double row 0.100" headers (see below) in a standard fashion for plugging into the BBI-64. So I bought this kit of crimp-pins and various header sizes:

Amazon.com: KINCREA Dupont Connector Kit —620 Pcs Crimp Housing Connector Kit with Dupont Wire Connectors-A Set of Male and Female 2.54 mm Dupont Connectors and Crimp Pins: Electronics

Amazon.com: KINCREA Dupont Connector Kit —620 Pcs Crimp Housing Connector Kit with Dupont Wire Connectors-A Set of Male and Female 2.54 mm Dupont Connectors and Crimp Pins: Electronics

www.amazon.com

Dual encoders use 5 inputs (inner L/R, outer L/R, push-button), plus GND wires = 2x5 female header.

Currently this prototype is just wood and hand drilled lexan. I have a roll of Carbon-fiber Vinyl which I intend to use to wrap the whole thing once I'm happy with it. I may have the final panels laser cut after I make any needed refinements.

I've already decided that a couple of things are too close to the side guards (brake bias, and a couple others. So, I'll probably widen the whole thing by 1-2" and respace everything to ensure a minimum clearance between everything.

The larger cockpit build is being done around the ergonomics of my real racecar (a 1990 Spec Miata). I have a spare set of miata pedals that I'm currently instrumenting with a 200 kg loadcell, and potentiometers for clutch/throttle. I also have a spare set of stalks and a ignition key...that I may wire up to another bodnar box.

Parts List

Single axis encoders with push. CTS288V232R161B2. Used for Brake Bias, and volume knobs.

288V232R161B2 CTS Electrocomponents | Sensors, Transducers | DigiKey

Order today, ships today. 288V232R161B2 – Rotary Encoder Mechanical 16 Quadrature (Incremental) Vertical from CTS Electrocomponents. Pricing and Availability on millions of electronic components from Digi-Key Electronics.

Dual axis encoders with push. No part# per se, just a web link. Used for sway-bar, and wing adjustments.

Dual Concentric Rotary Encoder Kit — PropWash Simulation - Flight Sim Radios, Panels, GPS for X-plane and FSX

Our PWS Dual concentric rotary encoder kit includes the encoder with switch, circuit board, nut, washer, headers and knobs. Black or Grey knobs are included. Perfect addon for flight simulation.

Joystick, 4 way switch. Again no part #, just ebay listing.

AC 240V 5A 4NO 4NC Momentary 2.5mm Fixing Thread Joystick Switch T1C2 | eBay

Find many great new & used options and get the best deals for AC 240V 5A 4NO 4NC Momentary 2.5mm Fixing Thread Joystick Switch T1C2 at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Raised Pushbutton switch (with LED). Ebay listing:

16mm Stainless Steel Momentary Push Button Switch with Yellow LED 845832027470 | eBay

Find many great new & used options and get the best deals for 16mm Stainless Steel Momentary Push Button Switch with Yellow LED at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Flush pushbutton (with LED). Ebay listing:

AngelEye Led 16mm 12V Stainless Steel Round Momentary Push Button Switch 4Colors | eBay

Find many great new & used options and get the best deals for AngelEye Led 16mm 12V Stainless Steel Round Momentary Push Button Switch 4Colors at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Various knobs. These shaft hole in these knobs were all about 0.010" too small for the CTS288 shaft. I drilled them out with a 1/4" drill bit to fit. Ebay listings:

2PCS AMPLIFIER KNOB 20x15.5mm Aluminum POTENTIOMETER VOLUME CONTROL Audio DIY | eBay

Find many great new & used options and get the best deals for 2PCS AMPLIFIER KNOB 20x15.5mm Aluminum POTENTIOMETER VOLUME CONTROL Audio DIY at the best online prices at eBay! Free shipping for many products!

www.ebay.com

1PC Solid Aluminum Knob 15x15mm Audio Potentiometer Volume Control Amplifier DIY | eBay

Find many great new & used options and get the best deals for 1PC Solid Aluminum Knob 15x15mm Audio Potentiometer Volume Control Amplifier DIY at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Black 25 x 15.5mm Aluminum 6mm Dia Rotary Control Potentiometer Cap Knob | eBay

Find many great new & used options and get the best deals for Black 25 x 15.5mm Aluminum 6mm Dia Rotary Control Potentiometer Cap Knob at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Brake Bias knob. Apex Sim Racing. I actully bought a different knob (that is 3d printed plastic), but Apex doesn't seem to sell it anymore. The closest is now billet machined (it looks nice, though twice the price):

Apex Sim Racing Billet Brake Bias Knob

Limited stock available Billet Aluminum Available in Anodized Black or Red Material: 6061 Billet Aluminum Total Diameter: 1.9" (48 mm) Interior Diameter: 38.5mm (Where Sticker Goes) Height: .78" (20mm) 2x m4 x 5mm grub screw Includes Apex + - Decal (see picture) Fits cts288 Encoder or any...

Switches. I'm not happy with the action of the switches. So, I won't bother listing those for now. When I decide on a replacement, I'll update this with that part.

Last edited: