Also try Dayton's DAEX30HESF, which while similar to the DAEX32EP, lack its steel spider:

Thank you, I followed your advice and switched to using DAEX30HESF. Either way all my 6 DAEX32EP-4 I have only two unbroken left (one was never used though). I managed to find a way to safely operate the DAEX32EP-4s with higher frequencies and not so much effects, but at the end after a month or two all of the broke - enormous waste of money.

Compared to them the DAEX30HESF are not so powerful, but yet again I am driving them at higher volume so it is almost comparable. Really liked the deep effect achievable with the EPs, as they have bigger moving mass multiplied by metal spider, but what can you do, nothing is perfect. Right now I am running for more than 2 months with four of them on the side of the seat back rest - still working great. At high volume they produce some noise, but I am able to use quite low frequencies and it is not really so much hearable.

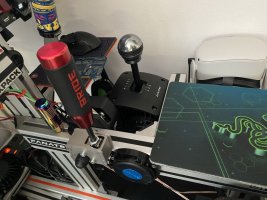

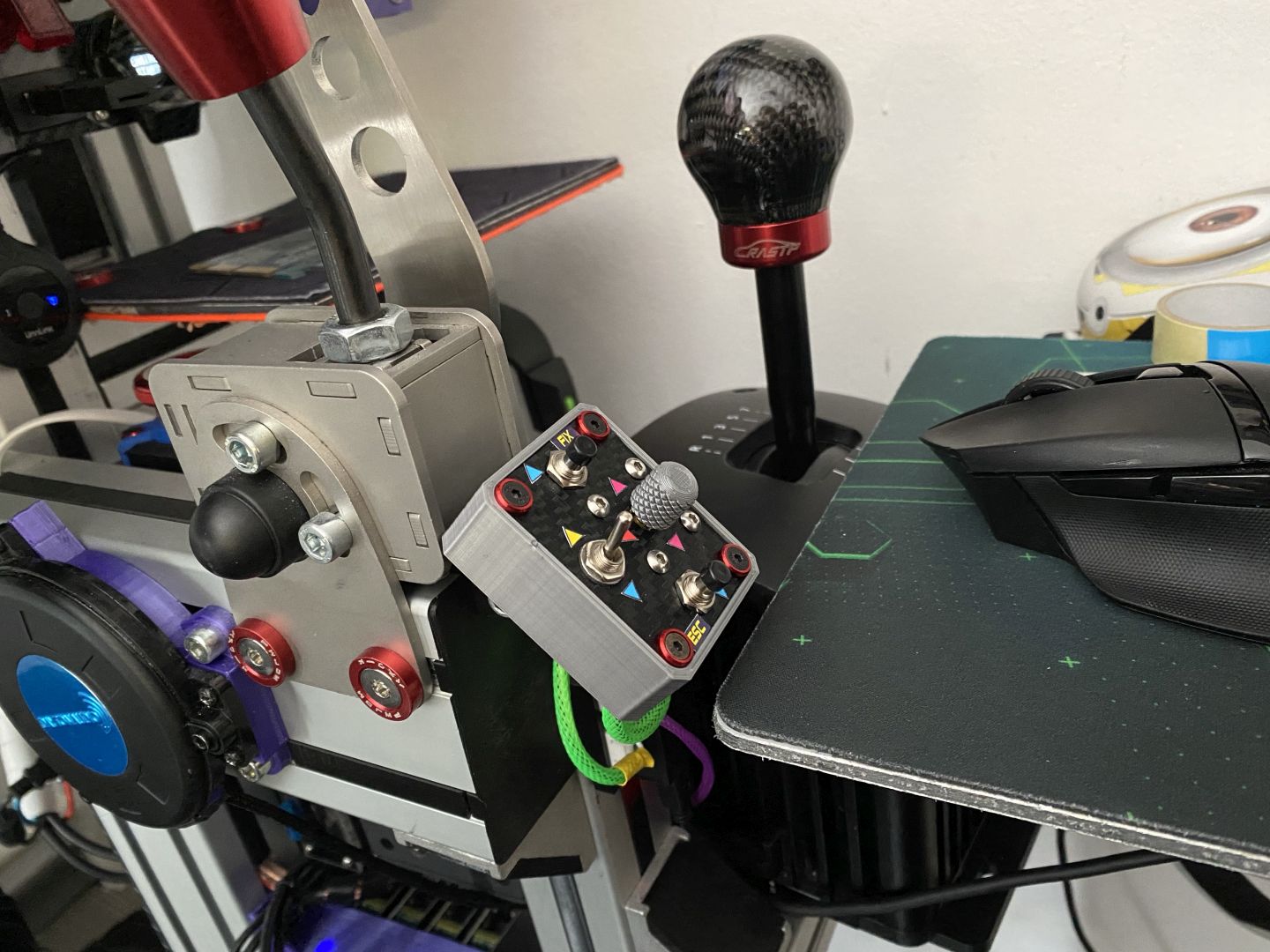

In the meantime I ordered also two Dayton DAEX58FP 25W exciters for testing purposes. They are OK, a little more powerful from the Pucks, but produce noise because of the plastic base they have. I also migrated to shorter 8040 shifter arm to separate the mouse pad and isolate as much as possible the shifter exciters:

The DAEX58FP worked fine with this application, but really did not like the rattle. Also it needed to work with a little higher frequencies. I also tried at that time to put the Dayton BST-2 at same place - again it produced the same perceivable effect, made no sense to use it for this purpose as there was literally no difference.

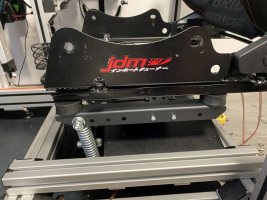

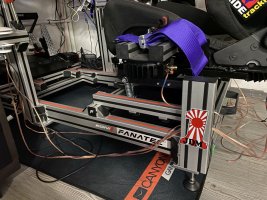

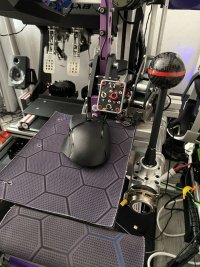

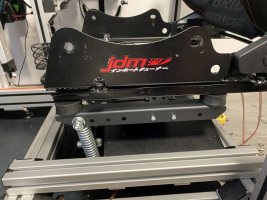

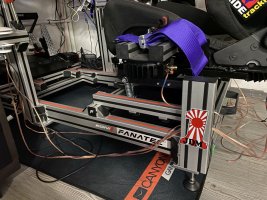

At the end I decided to give the Pucks one more go. It looked to me the default plastic mounts are not making good contact. I modified a design on Thingiverse for Dayton Puck holder and adjusted it to 8040 extrusion spacing. Now it works on both the alu profile and on the Fanatec shifter. At this time I have one on the side as pictured below and one on the other side mounted to the shifter. Both of them are connected in parallel to a single channel. This mount being lower profile the puck contacts directly with the surface beneath, now effect is better. I remained with this setup for the last 2-3 months, it is satisfactory. Wanted a little more pronounced effect, but still quite nice. Engine vibrations and gear change is felt very nicely in the Heusinkveld SQ shifter even with the bulky Bride handle (it is all aluminum, so it transfers vibrations well). When shifting with the SQ there is quite good deep vibration which compliments greatly its feel. When I try without vibrations it is immediately apparent something is missing. The Fanatec shifter also has very good solid feel, as log as the knob is in gear. The Puck vibrations are transduced much more effectively now, even with the aftermarket know (it is not solid, but has deep screw hole so now shifter is much shorter). Either way when driving it is most of the time in gear so I always feel the engine and when shifting have very satisfying additional jolt:

As I added Next Level V3 Motion platform shaker mount redesign was needed. I mounted them with two filed down Right angle brackets (they have longer screw hole) directly on the bolts holding the bottom part of the seat. It required a little convincing as it has about 5mm difference, but easily achievable. Belts are mounted on the third hole, as they have to be attached to the moving part of the platform:

Overall this was great improvement. Now I am driving the Auras at 70% volume and their effects are totally isolated from each other and easily felt on the side, as I would expect them to be. The feel is very direct and paired with the motion seat it is amazing. Seat is mounted on 4 rubber dampers only because seat mounting holes on platform and seat have 1cm difference between and I needed something to bridge it. Now everything is totally disconnected from the rig and vibrations stay in the seat exactly where they should be:

I bought one more Aura for pedal plate, so now both BST-1s are mounted on the seat. One is screwed directly to the back rest, the other is mounted below on one side to a 3030 extrusion and on the other directly to the lower seat. The 3030 profile itself is held by some washers on the side and zip-tied to the back brace of the seat. It also holds the very powerful 65kg belt tensioner, using it for months without issue - still solid construction:

The feel from both BST-1 on the seat with jump landing effect is amazing. I also put on them engine sound, but toned down as it is not very pleasant constantly rumbling on the back.

Having changed Dayton BST-1 for an Aura in front gave me opportunity to compare how both work. Auras are definitely better at very low frequencies, less than 40Hz. There they pack good punch, but from then up the feel I got was identical with both mounted below the pedal plate. With proper isolation and placement it looks at least to me some money can be saved with choosing Dayton over Aura. Yet again I still feel the Auras on the seat giving me better spectrum and more complete feel, is it worth the price difference - no idea.

I also switched to Heusinkveld Ultimate+ pedal set and Sim-Lab inverted mount. This required rework of the front bass shakers.

The central engine/jump landing was easy - just mounted on the top frame above pedals:

Bottom ones required some more imagination, I reused my previous idea and mounted them top down. They are isolated with rubber dampers from frame, both are separate and pedal plate will screw on each side hoping I will have distinctive left and right:

All of this was mounted together on the rig:

The top bass shaker feels quite well. Some vibrations propagate through the frame, but are dampened a lot from the side plates. I was thinking on a solution to dampen them, but after testing realized it is not that needed, especially when I am using it for gear and engine effects. It dampens enough that I do not feel delayed vibrations someplace else on the rig.

The bottom shakers are another story. I am still being plagued by vibrations everywhere in the rig coming from the front "wheels". This is mainly due to the dampers design, the bolt that holds the pedal plate goes in, touches the bottom mount and literally the damper is bypassed. I fixed them before by somewhat keep the V3 plates not very tight. Also I think the bottom inbuilt screw in the damper is a little long and touches the profile, I have to keep them a little unwound to minimize vibrations. As I really had no time to deal with it tested it like that - still works good, top shaker is fine, but loosing bottom ones feel. I am waiting some other dampers now, little smaller but with built in screws on both side. They should be rubber all the way and have no other mechanical connection, based on the experience I have with isolating the seat I hope they will do the trick.