Hi.

TLDR:

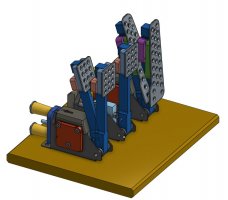

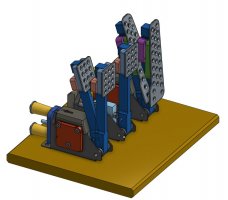

I made a Pedal Box using Aliexpress Hand Brake. V1 was hydraulic and now, V2 is Load Cell based. (now go watch the pictures )

)

TL Did R:

Around 2017 I decided to make my own Pedal Box. Because I like the challenge of building good quality stuff on a budget, I was searching the best alternative for a DIY Pedal Box.

Started looking for the OBP pedal box, but 2 problems came up: first, was the price, not budget friendly; Second, I was going for the hydraulic root and wanted to reduce the chances of oil leaks. A complete pedal box comes with 2 brake master cylinders and I didn’t want to manage 3 master cylinders (the clutch was going to be hydraulic too)... Because of that, I went in the direction of an individual 3 pedal set. One accelerator, one brake and one clutch. With the advantage I could play with the position of the pedals separately.

OBP offers the individual pedal set. But buying 3 would be too expensive… (today, around £410+shipping)

Then I had the idea of using a Hand brake. Since the handbrake uses the same master cylinder system as the brake pedal. I went online looking for the cheap/stable handbrake money could buy. I found the best option was this:

NOTE: The price is always changing in Aliexpress.

When I wrote this text, this was the price with shipping to Europe: +-30€x3 = 90€ (more less the same I paid 5 years ago). Sometimes it is more expensive…

And it is easy to modify and convert to Accelerator/Brake/Clutch pedal. Just cut the top of the handle, drill a hole and attach a pedal face. (I bought OMP pedal face)

More pics from the Version 1.0 here:

I used them for almost 2 years without any problems and was really happy with them. But after the birth of my second child, I had to put the sim racing aside. So, the pedals and rig went to the basement.

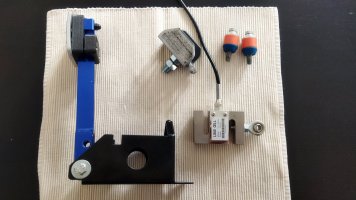

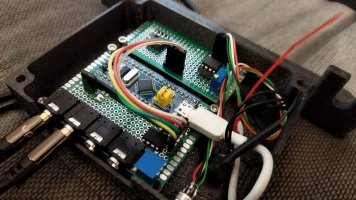

Version 2.0

Fast forward some years, my kids are big enough, so I can focus some energy on sim racing again. It was time to rebuild the pedals. But everything went downhill this time… After disassembling all the pedals and hydraulic fitting to clean everything, I wasn't able to avoid oil leaks. The rubber of the master and/or slave cylinder couldn’t seal any more. Then I had leaks in the fittings… There was oil everywhere. My wife wasn’t happy. I wasn’t happy… I said F this… I will go the Load Cell way.

Having a 3d printer now, I was able to design something better than the last time (I used a kitchen cutting board for the plates that hold the springs and hand saw them).

So, after some prototypes, I am finally happy enough with my last iteration of the pedals and would like to share them.

Onshape 3d model link:

cad.onshape.com

Google photos Album link:

cad.onshape.com

Google photos Album link:

Declaimer: This is not a "How to do it". Just an example of what can be made. Most of the solutions and decisions were made because of the available hardware I accumulated along the time, like springs and bolts, magnets, etc.

TLDR:

I made a Pedal Box using Aliexpress Hand Brake. V1 was hydraulic and now, V2 is Load Cell based. (now go watch the pictures

TL Did R:

Around 2017 I decided to make my own Pedal Box. Because I like the challenge of building good quality stuff on a budget, I was searching the best alternative for a DIY Pedal Box.

Started looking for the OBP pedal box, but 2 problems came up: first, was the price, not budget friendly; Second, I was going for the hydraulic root and wanted to reduce the chances of oil leaks. A complete pedal box comes with 2 brake master cylinders and I didn’t want to manage 3 master cylinders (the clutch was going to be hydraulic too)... Because of that, I went in the direction of an individual 3 pedal set. One accelerator, one brake and one clutch. With the advantage I could play with the position of the pedals separately.

OBP offers the individual pedal set. But buying 3 would be too expensive… (today, around £410+shipping)

Then I had the idea of using a Hand brake. Since the handbrake uses the same master cylinder system as the brake pedal. I went online looking for the cheap/stable handbrake money could buy. I found the best option was this:

NOTE: The price is always changing in Aliexpress.

When I wrote this text, this was the price with shipping to Europe: +-30€x3 = 90€ (more less the same I paid 5 years ago). Sometimes it is more expensive…

And it is easy to modify and convert to Accelerator/Brake/Clutch pedal. Just cut the top of the handle, drill a hole and attach a pedal face. (I bought OMP pedal face)

More pics from the Version 1.0 here:

I used them for almost 2 years without any problems and was really happy with them. But after the birth of my second child, I had to put the sim racing aside. So, the pedals and rig went to the basement.

Version 2.0

Fast forward some years, my kids are big enough, so I can focus some energy on sim racing again. It was time to rebuild the pedals. But everything went downhill this time… After disassembling all the pedals and hydraulic fitting to clean everything, I wasn't able to avoid oil leaks. The rubber of the master and/or slave cylinder couldn’t seal any more. Then I had leaks in the fittings… There was oil everywhere. My wife wasn’t happy. I wasn’t happy… I said F this… I will go the Load Cell way.

Having a 3d printer now, I was able to design something better than the last time (I used a kitchen cutting board for the plates that hold the springs and hand saw them).

So, after some prototypes, I am finally happy enough with my last iteration of the pedals and would like to share them.

Onshape 3d model link:

Onshape

Sign in to Onshape, the #1 fastest growing CAD system in the world with over 4 million users.

Declaimer: This is not a "How to do it". Just an example of what can be made. Most of the solutions and decisions were made because of the available hardware I accumulated along the time, like springs and bolts, magnets, etc.

Last edited: