Hello !

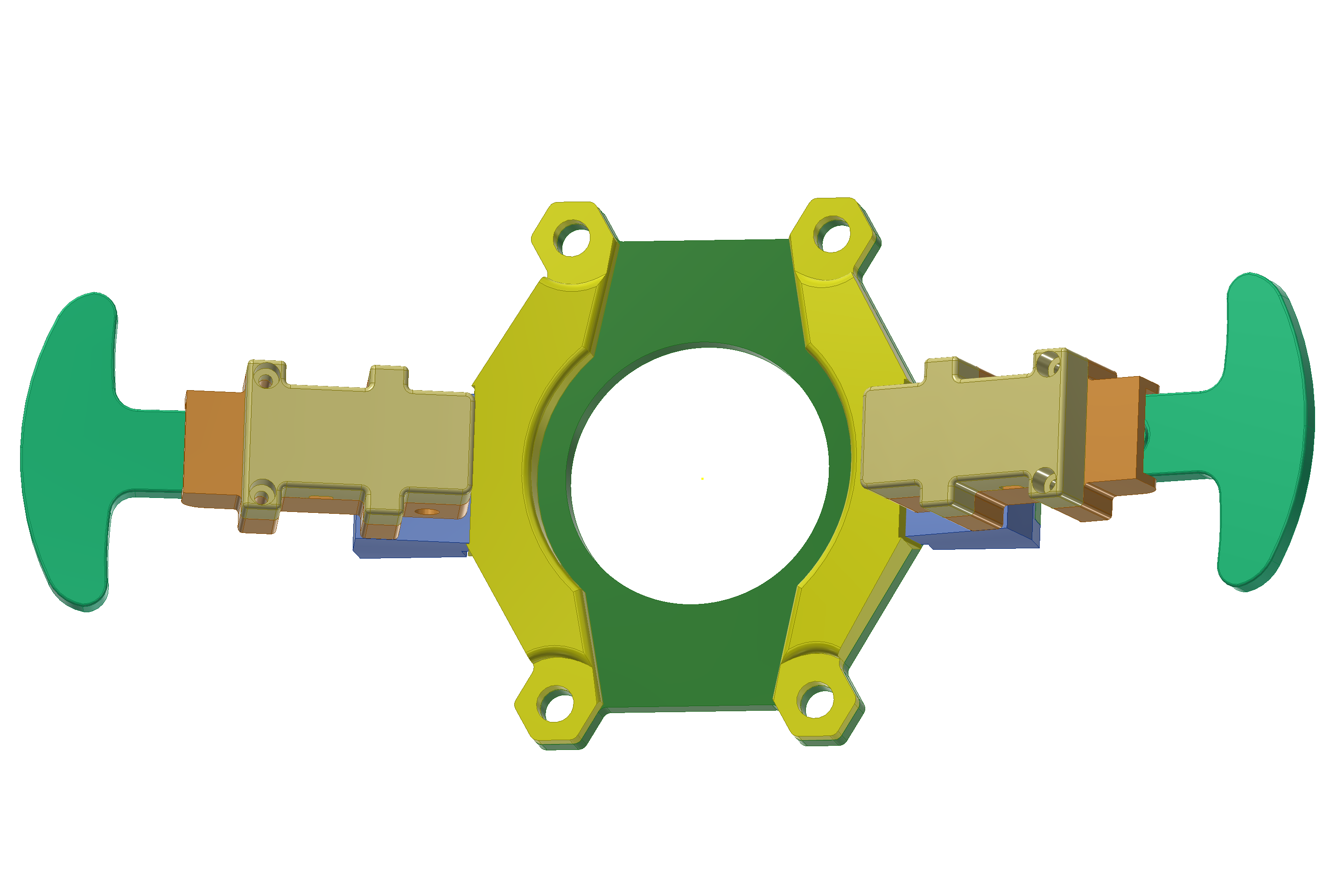

I build a complete static paddles for Fanatec wheelbases, including the electronics needed to connect the paddles to the SHIFTER2 port. The main advantage of this project is that you can design your own sequential shifter and plug it into the base directly, avoiding using a microcontroller (and a usb port). All the parts are 3D printed.

GitHub page (Fanashifter)

I build a complete static paddles for Fanatec wheelbases, including the electronics needed to connect the paddles to the SHIFTER2 port. The main advantage of this project is that you can design your own sequential shifter and plug it into the base directly, avoiding using a microcontroller (and a usb port). All the parts are 3D printed.

GitHub page (Fanashifter)