Thought it might be an idea to share some ideas @Neilski and I have been bouncing around about replacing the stock pots in the G27 and G29 with Hall Sensors (probably also work on a G25). We found a few discontinued options (e.g. https://www.simulaje.com/productos/accesorios/sensor-hall.html) and a current one that seemed ok but required a USB adapter (https://tomyracing.com/index.php?language=en&module=products&content=pedhallv130), which made us suspect its range might not be great and/or it didn't invert the signal. (EDIT: I didn't read the description properly! the mod can be used without a USB adapter)

So, in the interests of science we decided to get some bits and have a play. We went for the A1324/5/6 (https://docs.rs-online.com/958c/0900766b813d193a.pdf) as it appeared to have decent range of close to 0-Vcc (many are just +/-1v) and @Neilski worked out a simple arrangement that theoretically would produce a near linear change based on angle over the 70 deg the G2X rotates the pot:

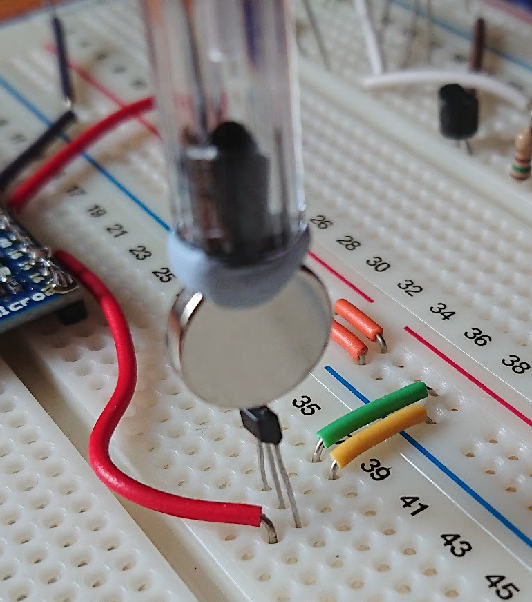

This was then a great excuse to get a 3D printer, so I ordered an Ender 3 Pro (https://www.creality3dofficial.com/products/creality-ender-3-pro-3d-printer) and knocked up a simple model to hold the magnet and sensor whilst still utilising the existing pot for simplicity. The result was the following:

Assembled and connected up to an Arduino to measure against the pot

It's got an interference fit that seems fine and allows adjustment of the sensor angle to get the range as centred on Vcc/2 as possible. We played with some different magnet sizes, but found the 8mm with the most sensitive device (A1324) gave a range just over that of the stock pot. BLUE line is the pot, RED is the hall sensor

We are still playing but this is looking really promising as a simple swap for the standard pots in the G27 and everything but brake in a G29, although a less sensitive device like the A1326 could probably get the range down to that expected (more testing required!)

EDIT: forgot the link to the 8mm model - https://a360.co/3mvHXkX

So, in the interests of science we decided to get some bits and have a play. We went for the A1324/5/6 (https://docs.rs-online.com/958c/0900766b813d193a.pdf) as it appeared to have decent range of close to 0-Vcc (many are just +/-1v) and @Neilski worked out a simple arrangement that theoretically would produce a near linear change based on angle over the 70 deg the G2X rotates the pot:

This was then a great excuse to get a 3D printer, so I ordered an Ender 3 Pro (https://www.creality3dofficial.com/products/creality-ender-3-pro-3d-printer) and knocked up a simple model to hold the magnet and sensor whilst still utilising the existing pot for simplicity. The result was the following:

Assembled and connected up to an Arduino to measure against the pot

It's got an interference fit that seems fine and allows adjustment of the sensor angle to get the range as centred on Vcc/2 as possible. We played with some different magnet sizes, but found the 8mm with the most sensitive device (A1324) gave a range just over that of the stock pot. BLUE line is the pot, RED is the hall sensor

We are still playing but this is looking really promising as a simple swap for the standard pots in the G27 and everything but brake in a G29, although a less sensitive device like the A1326 could probably get the range down to that expected (more testing required!)

EDIT: forgot the link to the 8mm model - https://a360.co/3mvHXkX

Last edited: