I read a couple of threads here and I believe I am posting at the right place. If not, my sincerest apologies and I will delete this post myself.

-Long story short: I want to find a 50.8mm to 70mm converter like the image shown below, but without tapped holes. I have searched for a long time on amazon and ebay. For every single converter/wheel spacer I saw, either the 70mm side is tapped or the 50.8mm side is tapped. I am getting a little desperate. (Even the adapters sold at leo bodnar and cube control's website are tapped at one side.)

-Why would I need something that weird?

I have recently been expanding my steering wheel collection. Bought some wheels from forum members (Hope I can show them soon. ) and some from online store. One of them is the cube control formula pro, which has an tapped 50.8 pattern like below.

) and some from online store. One of them is the cube control formula pro, which has an tapped 50.8 pattern like below.

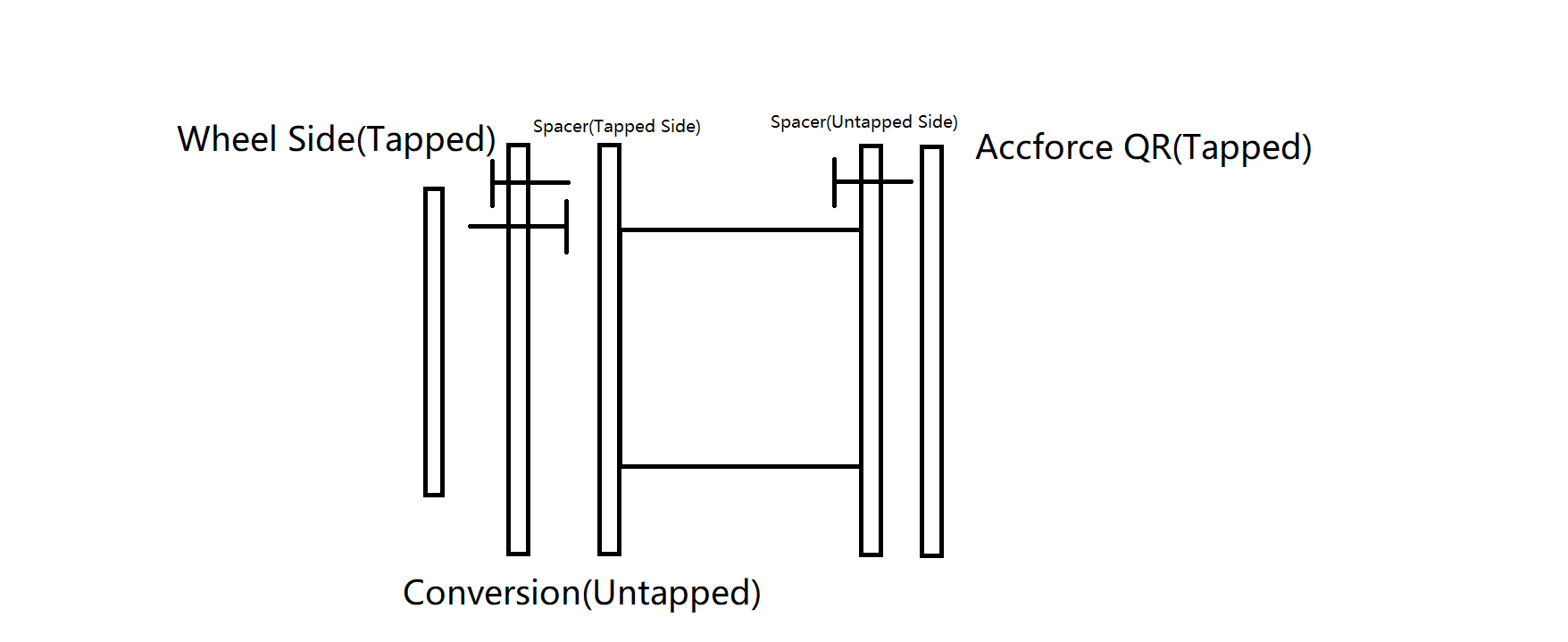

I have an accuforce v2. Accuforce has 70mm QR. Then here is where the problem comes in. The ideal situation will be like this ("T" shaped things are bolts):

Please be aware that most spacers on the market are tapped on one side and untapped on the other side.

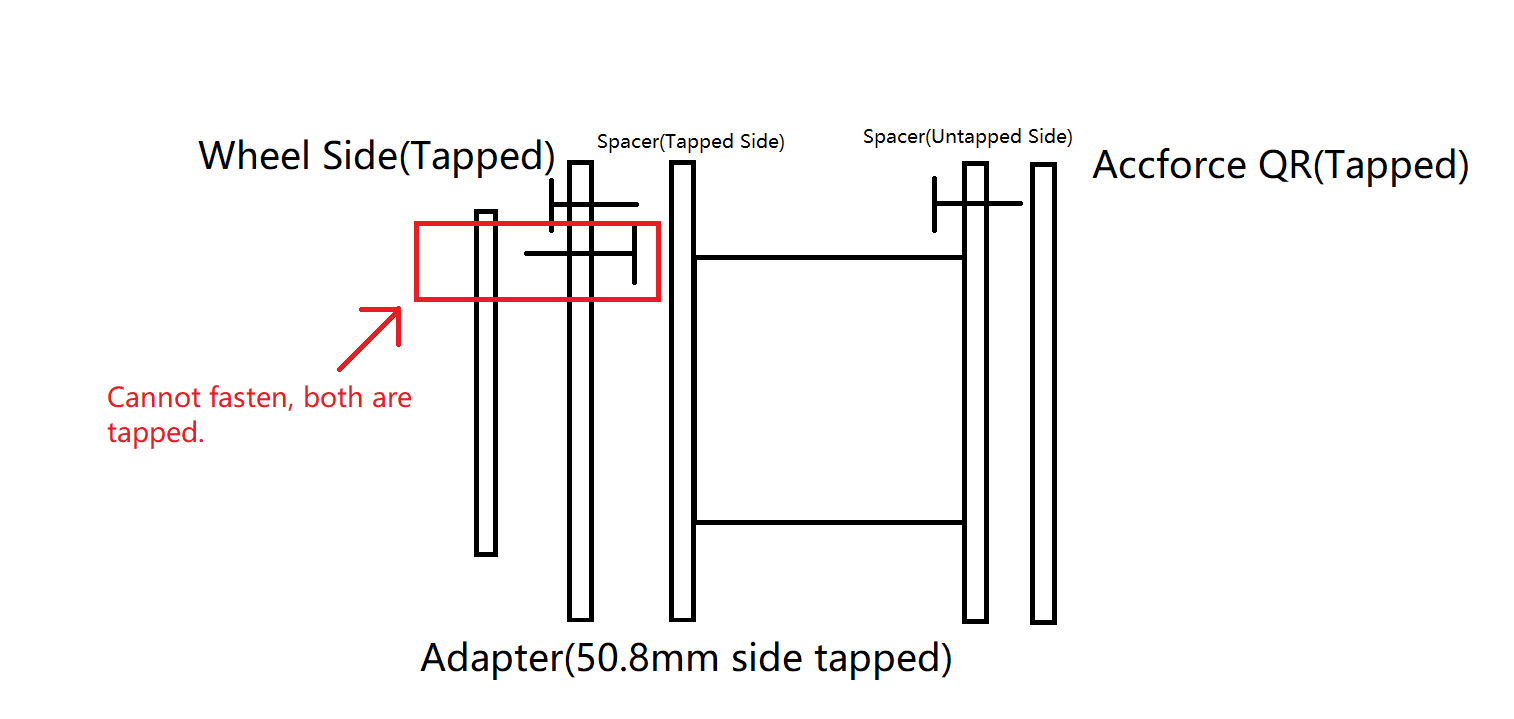

Now with the adapter I showed at the beginning, I am going to have a problem:

This one tiny details gave me a loooooot of headache. I searched for days and no avail. So there are several possible ways to solve this problem.

1. Open the wheel and change the converter.

Well this should be the standard way to do so. However, I watched Barry's review:

I realize that to get to the bolts I need to remove all the wiring and the PCB. I am afraid that I might hurt the components during the process. I don't think I am the most careful person out there.

2. Oh god just buy that goddamn tapped adapter and remove the tapping.

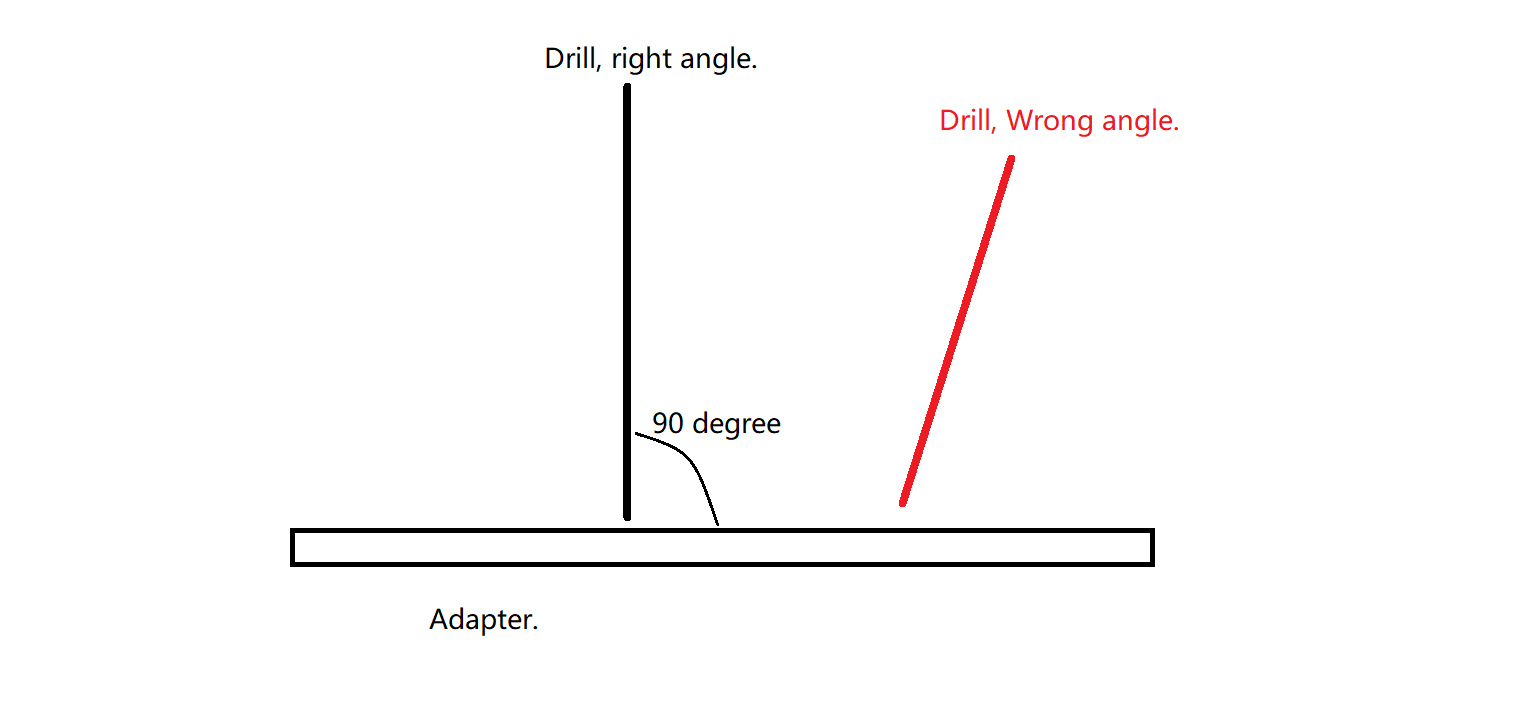

Ahh yes that was what first came into my mind. That adapter just costs me around 30 USD so in the worst case I will just throw 30 bucks into the water. But....How do I remove the tapping accurately? Maybe I can use a heavy duty drill but how can I point the drill perfectly perpendicular to the surface of the adapter? I guess I need some device in the factory.

I don't think with the current consumer grade tools I have I will be able to hold 90 degrees from the start to end...

So that should be the whole story. I would greatly appreciate it if you can give me some advice. I know I am currently in a dumb situation. I open to any criticism.

Any mocking, of course, if you cannot tolerate my stupidity in this thread.

-Long story short: I want to find a 50.8mm to 70mm converter like the image shown below, but without tapped holes. I have searched for a long time on amazon and ebay. For every single converter/wheel spacer I saw, either the 70mm side is tapped or the 50.8mm side is tapped. I am getting a little desperate. (Even the adapters sold at leo bodnar and cube control's website are tapped at one side.)

-Why would I need something that weird?

I have recently been expanding my steering wheel collection. Bought some wheels from forum members (Hope I can show them soon.

I have an accuforce v2. Accuforce has 70mm QR. Then here is where the problem comes in. The ideal situation will be like this ("T" shaped things are bolts):

Please be aware that most spacers on the market are tapped on one side and untapped on the other side.

Now with the adapter I showed at the beginning, I am going to have a problem:

This one tiny details gave me a loooooot of headache. I searched for days and no avail. So there are several possible ways to solve this problem.

1. Open the wheel and change the converter.

Well this should be the standard way to do so. However, I watched Barry's review:

I realize that to get to the bolts I need to remove all the wiring and the PCB. I am afraid that I might hurt the components during the process. I don't think I am the most careful person out there.

2. Oh god just buy that goddamn tapped adapter and remove the tapping.

Ahh yes that was what first came into my mind. That adapter just costs me around 30 USD so in the worst case I will just throw 30 bucks into the water. But....How do I remove the tapping accurately? Maybe I can use a heavy duty drill but how can I point the drill perfectly perpendicular to the surface of the adapter? I guess I need some device in the factory.

I don't think with the current consumer grade tools I have I will be able to hold 90 degrees from the start to end...

So that should be the whole story. I would greatly appreciate it if you can give me some advice. I know I am currently in a dumb situation. I open to any criticism.

Any mocking, of course, if you cannot tolerate my stupidity in this thread.