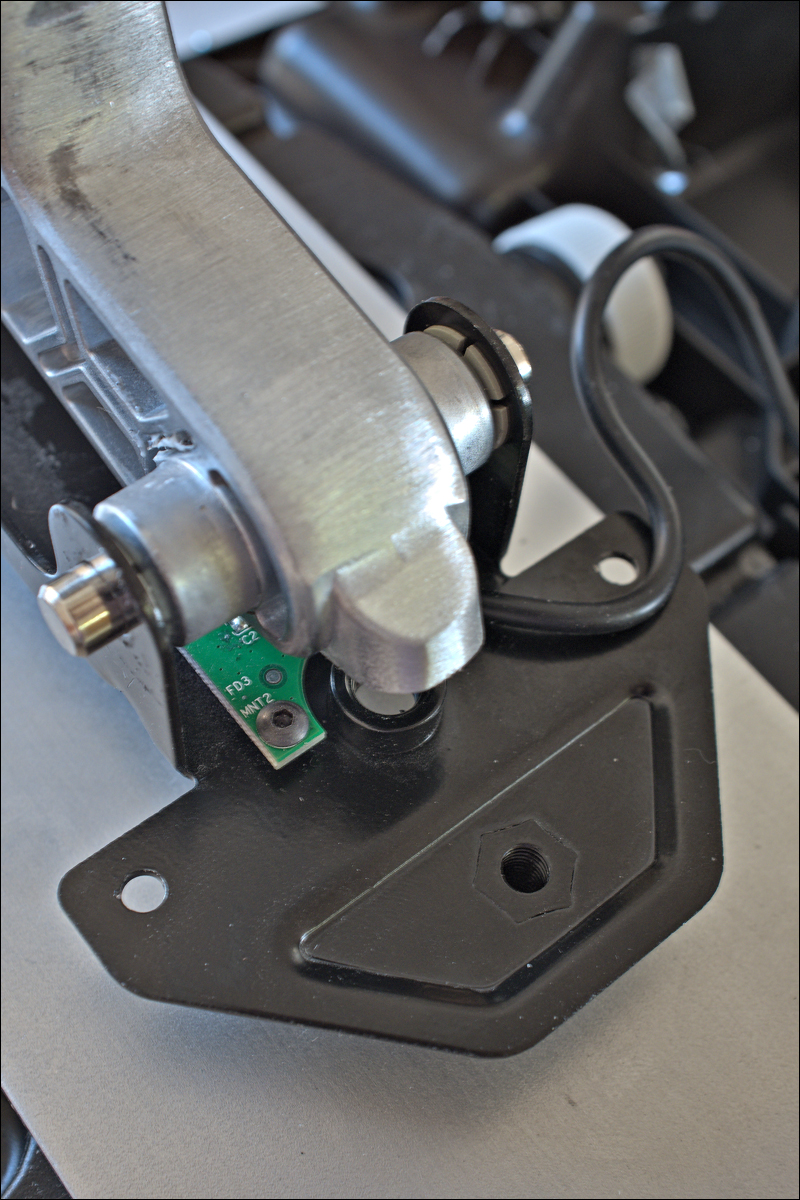

as I expected, the mounts for the clutch, brake, and throttle pedals are fundamentally the same, as this photo of the clutch pedal mounted in the brake pedal bracket (complete with Hall sensor circuit board, which screws into existing M2.5 holes!) proves:

While I am happy overall with the performance of the T-LCM pedals, especially for their modest price, they don't fit my 13EEE feet very well. Worse, because the pedal spacing isn't adjustable, there isn't much I can do to improve upon this situation without significantly modifying them.

I'm not opposed to modifying them, but at present, I have limited resources available to me, so if I decide to do so, whatever modifications I make cannot require any machining or welding, as this is beyond my capability now that I no longer have free access to a machine shop. (Note: I'm able to cut, shape, smooth, and finish aluminum, as well as bend it and drill holes in it, but working with steel is a bit more of a challenge.)

Anyway, not having much else to do today, I decided to explore the idea of modifying my T-LCM pedals to make the pedal spacing adjustable and disassembled them to see what Thrustmaster has given me to work with and/or around.

Since I had them apart, I also took the opportunity to measure some things, such as the amount of side-to-side play each pedal has after nearly 800 hours -- !!! -- of use over the past year (clutch = ~.062", brake = ~.033", throttle = ~.125", as measured at the top of the pedals proper, not the pedal faces) and the clutch and throttle spring wire diameters (clutch = ~1.87 mm, throttle = ~1.5 mm, so the clutch pedal really is stiffer than the throttle pedal) and see how many parts can be interchanged, potentially to improve their overall performance via some clever mixing-and-matching.

Which is how I came to mount the clutch pedal in the brake pedal bracket. Although the brake pedal pin has a circlip on each end and is the same nominal 8 mm diameter as the pins for the clutch and throttle pedals, it's ~5 mm shorter, due to the fact the steel brake mounting bracket is thinner than the molded plastic brackets for the other two pedals. All three pedals also share the same plastic bushings, although in the case of my pedals, the throttle pedal bushings have worn noticeably, which is probably why its side-to-side play measured twice that of the clutch pedal.

(While the molded plastic clutch and throttle mounting brackets do flex about twice as much as the brake pedal's steel bracket when subjected to side loads, the holes remain circular, not oval, and the pins still fit in them fairly tightly. I know many people have expressed concern about the long-term reliability of plastic used for this purpose, but with my pedals, the cause of the excessive side-flex of the throttle pedal is due to bushing wear, not bracket wear. I saw no cracks or other evidence that would suggest the molded plastic mounting brackets are being stressed anywhere near their yield strength, let alone beyond it.)

Back to modifying my pedals to make the spacing between them adjustable: If Thrustmaser will sell the steel brake pedal mounting bracket as a spare part and price it affordably, then it'll be a relatively easy matter to simply remove the "guts" of the T-LCM pedal from the OEM molded plastic base and remount them on individual pieces of .25" aluminum plate such that they can be readily and easily repositioned as necessary to comfortably fit any size feet.

If not, it should also be possible to fabricate an equivalent mounting bracket using pieces of .25" aluminum angle and basic DIY tools (drill press, disc sander, hacksaw, files, sandpaper, etc.) for not a lot of money or effort.

I haven't yet decided which route I'm going to pursue, but based on what I saw today, I definitely am going to disembowel my T-LCM pedals and mount each pedal on a separate mounting plate, so I can finally position them optimally for my feet and my sim-rig. 8^)

While I am happy overall with the performance of the T-LCM pedals, especially for their modest price, they don't fit my 13EEE feet very well. Worse, because the pedal spacing isn't adjustable, there isn't much I can do to improve upon this situation without significantly modifying them.

I'm not opposed to modifying them, but at present, I have limited resources available to me, so if I decide to do so, whatever modifications I make cannot require any machining or welding, as this is beyond my capability now that I no longer have free access to a machine shop. (Note: I'm able to cut, shape, smooth, and finish aluminum, as well as bend it and drill holes in it, but working with steel is a bit more of a challenge.)

Anyway, not having much else to do today, I decided to explore the idea of modifying my T-LCM pedals to make the pedal spacing adjustable and disassembled them to see what Thrustmaster has given me to work with and/or around.

Since I had them apart, I also took the opportunity to measure some things, such as the amount of side-to-side play each pedal has after nearly 800 hours -- !!! -- of use over the past year (clutch = ~.062", brake = ~.033", throttle = ~.125", as measured at the top of the pedals proper, not the pedal faces) and the clutch and throttle spring wire diameters (clutch = ~1.87 mm, throttle = ~1.5 mm, so the clutch pedal really is stiffer than the throttle pedal) and see how many parts can be interchanged, potentially to improve their overall performance via some clever mixing-and-matching.

Which is how I came to mount the clutch pedal in the brake pedal bracket. Although the brake pedal pin has a circlip on each end and is the same nominal 8 mm diameter as the pins for the clutch and throttle pedals, it's ~5 mm shorter, due to the fact the steel brake mounting bracket is thinner than the molded plastic brackets for the other two pedals. All three pedals also share the same plastic bushings, although in the case of my pedals, the throttle pedal bushings have worn noticeably, which is probably why its side-to-side play measured twice that of the clutch pedal.

(While the molded plastic clutch and throttle mounting brackets do flex about twice as much as the brake pedal's steel bracket when subjected to side loads, the holes remain circular, not oval, and the pins still fit in them fairly tightly. I know many people have expressed concern about the long-term reliability of plastic used for this purpose, but with my pedals, the cause of the excessive side-flex of the throttle pedal is due to bushing wear, not bracket wear. I saw no cracks or other evidence that would suggest the molded plastic mounting brackets are being stressed anywhere near their yield strength, let alone beyond it.)

Back to modifying my pedals to make the spacing between them adjustable: If Thrustmaser will sell the steel brake pedal mounting bracket as a spare part and price it affordably, then it'll be a relatively easy matter to simply remove the "guts" of the T-LCM pedal from the OEM molded plastic base and remount them on individual pieces of .25" aluminum plate such that they can be readily and easily repositioned as necessary to comfortably fit any size feet.

If not, it should also be possible to fabricate an equivalent mounting bracket using pieces of .25" aluminum angle and basic DIY tools (drill press, disc sander, hacksaw, files, sandpaper, etc.) for not a lot of money or effort.

I haven't yet decided which route I'm going to pursue, but based on what I saw today, I definitely am going to disembowel my T-LCM pedals and mount each pedal on a separate mounting plate, so I can finally position them optimally for my feet and my sim-rig. 8^)