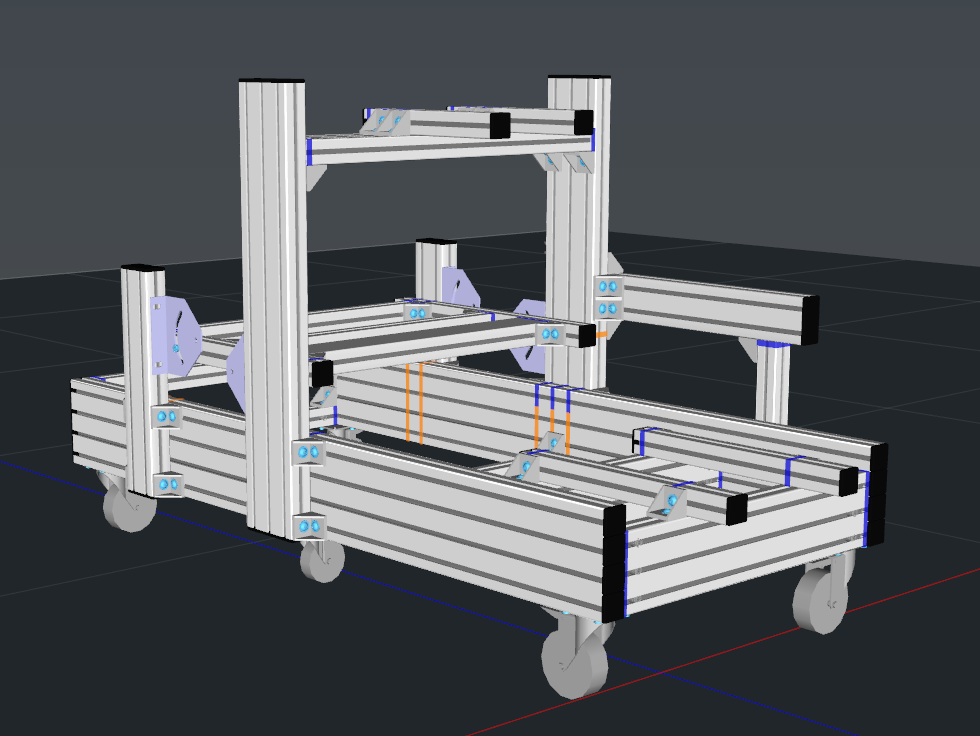

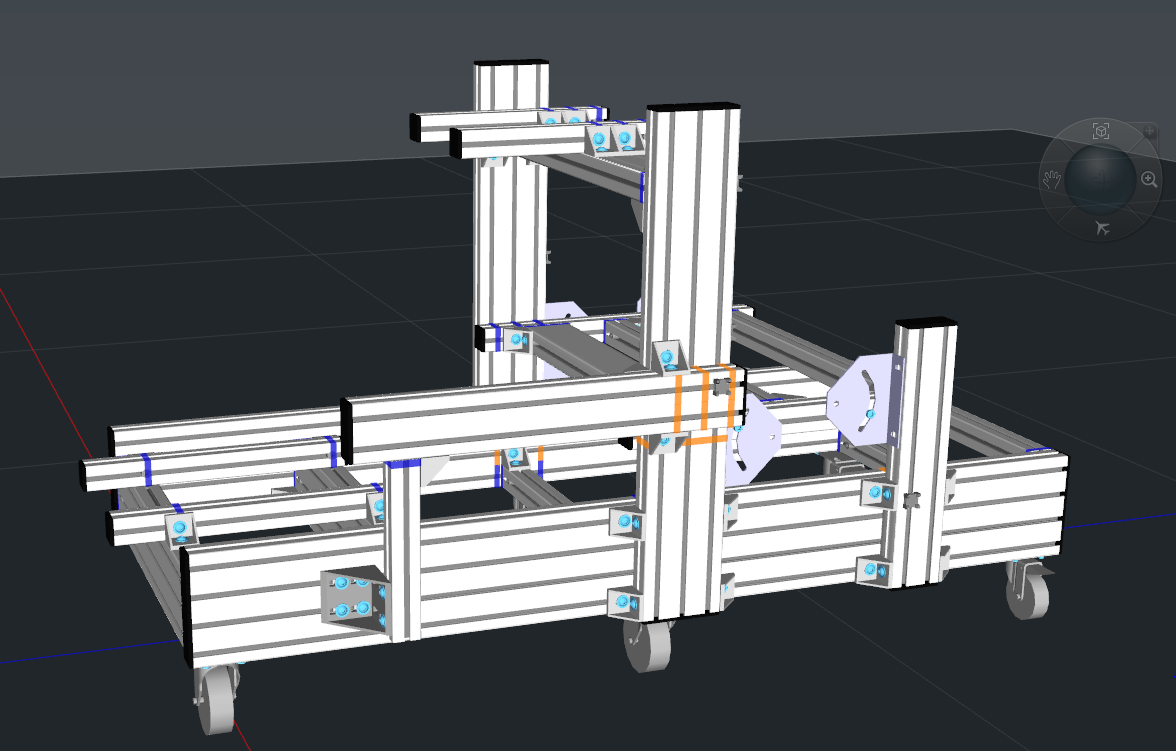

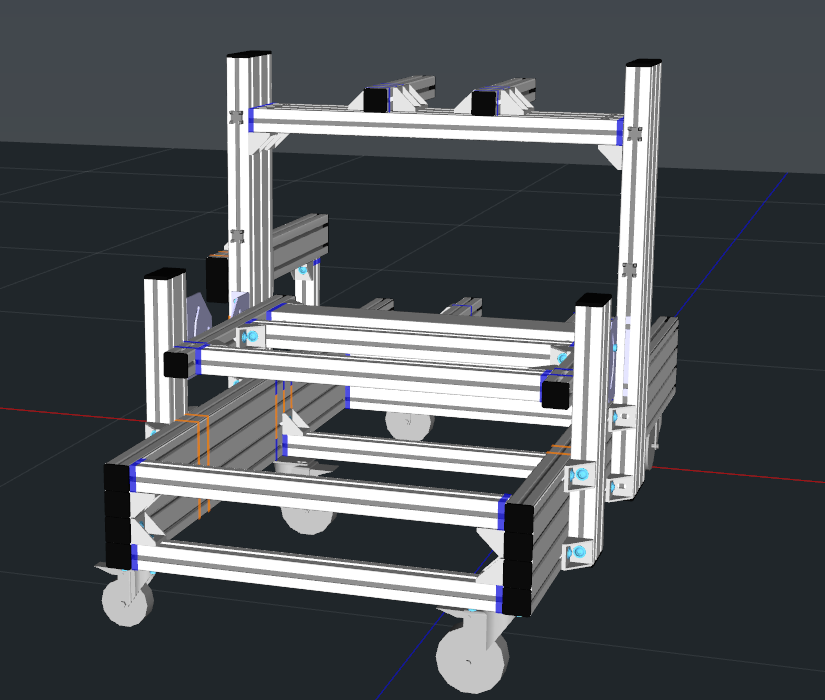

Looking to build a hybrid GT1 rig/ P1-X with slight modifications, let me know your opinion:

Length = 1.35m, width of wheel deck = 0.64m and the height is 0.71m. I'm looking for something sturdy with no flex to hold a SC 2 Pro or something along those lines with a dd wheel and I need a rig to last a long time and provide a base for future upgrades. Planning on adding a Sparco R100 for the reclining back. Let me know what advice you have...

Also, people that own a GT1 or P1-X what improvements would you suggest on the overall chassis design, i'm average hegith just about 6ft and weigh 76kg.

Length = 1.35m, width of wheel deck = 0.64m and the height is 0.71m. I'm looking for something sturdy with no flex to hold a SC 2 Pro or something along those lines with a dd wheel and I need a rig to last a long time and provide a base for future upgrades. Planning on adding a Sparco R100 for the reclining back. Let me know what advice you have...

Also, people that own a GT1 or P1-X what improvements would you suggest on the overall chassis design, i'm average hegith just about 6ft and weigh 76kg.