Peter Koslowski

TIKAL SPORT

About two weeks ago I ordered the Simrig SR-1 Motion System from Simrig. After I had sent an email asking how long the actuators would last and Sebastian from Simrig sent me back that they had the system running for 400 hours now and there would have been no fatigue, I said to myself, so I buy this now! 2900 € with shipping is not little money but other systems with 3DOF are always above that. Ok, I transferred the money via paypal and hoped that it would come quickly. And it came quickly. Within a week it was there and I had sweaty hands! The installation to my rig did not take six hours and I was full of anticipation like a little boy for Christmas!

Wow, the first laps of Raceroom with the BMW DTM 2016 on the Nordschleife blew me away! Everything went very well, and my previous concerns, like no power, little distance, weaker electric motors, worm gears, rack and pinion gears were no longer there. Actually I had considered the SFX-100 system or the PT actuators, maybe the Frex as well. But the effort and the additional equipment and probable trouble with some non-functioning parts kept me from going that other way.

After these two weeks I don't regret the purchase.

Unfortunately I don't have the possibility to test the other systems, but I think that you can make comparisons on Youtube and see how powerful the Simrig system is.

Well, one limitation should be mentioned, because the actuators are designed with 50kg each, that means, the Monster Rigs, which were built for heavy people and actually not existing loads, can not be operated with the SR-1. My rig weighed without the SR-1 system with the Fanatac Podium DD2, the CSP V3, Sparco R100 seat and the aluminum profiles exaggerated 60 kg. With the SR-1 system approx. 75kg. I am slim and when I have eaten the Christmas goose I weigh 75kg. So 150Kg are to be mastered and the SR-1 system manages that without complaining.

The 100mm/s give a comparable angular speed to the other systems due to the close positioning of the actuators. I would also describe the response behavior of the actuators as brutal. The volume is audible but not very disturbing. What's a bit annoying is the mechanical play, which causes a clear crackling when counter-movements occur. With the supplied software, however, a smoother response can be set and the clattering disappears almost completely.

Unfortunately, the cooling of the power supply is a complete construction error. A three centimeter fan with approx. 5000 rpm screams the heat out of the case. It starts every 10min.

Here you see the actuator. Almost the entire part was produced in 3D printing. The motor drives the rack in the actuator with a worm gear.

The assembly is relatively simple. Two 20x20 aluminum profiles are screwed under the rig to which the actuators are attached. The side brackets of the actuators are specially made for different sizes.

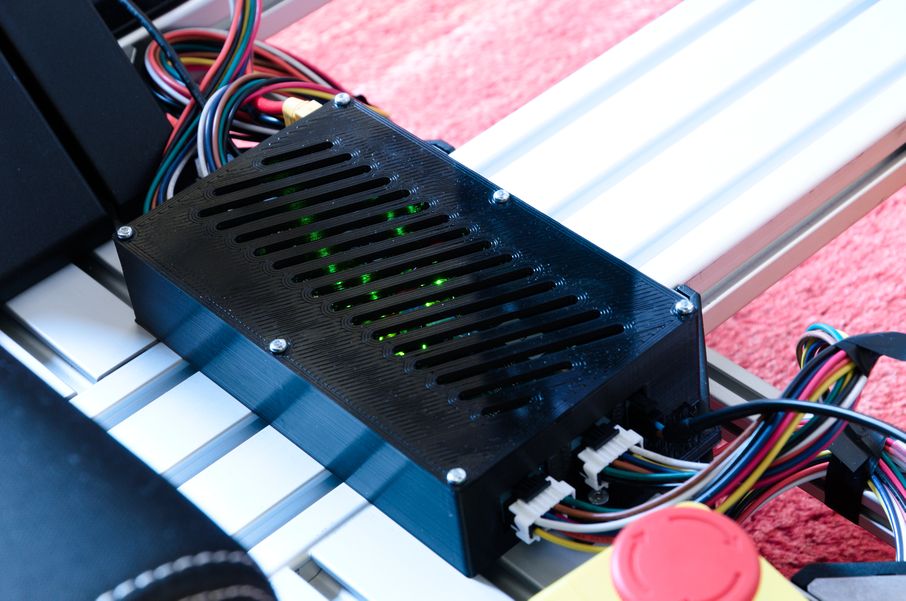

A single control unit supplies the actuators with the required voltage and current. This is very practical as you don't need an additional rack for control units.

In total my rig weighs about 75kg now, so people with up to 100kg live weight could have fun.

I can screw on these rollers quickly and the relatively low weight of the rig keeps it mobile.

The power supply unit stands out due to its enormous noise development. Maybe I'll put on a hand there and install a bigger and quieter fan. But I would have to cut a hole in the case cover. But, what the hell!

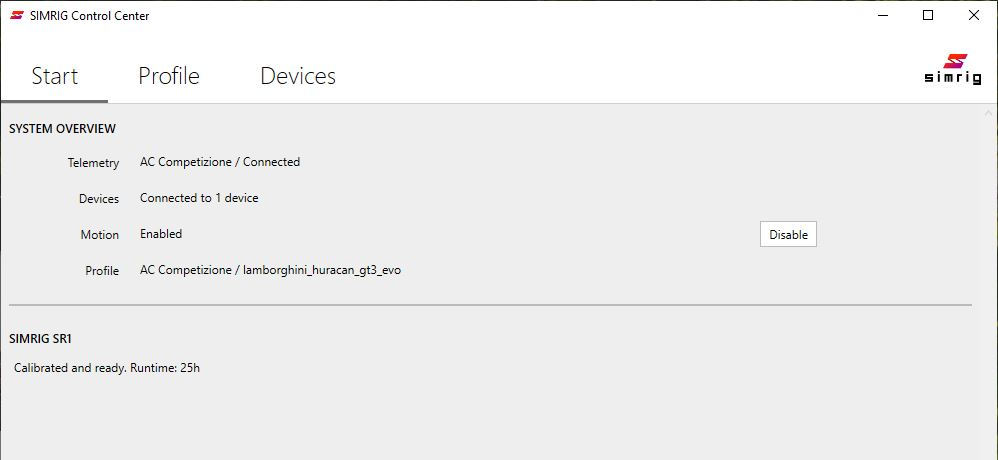

Start screen of the software.

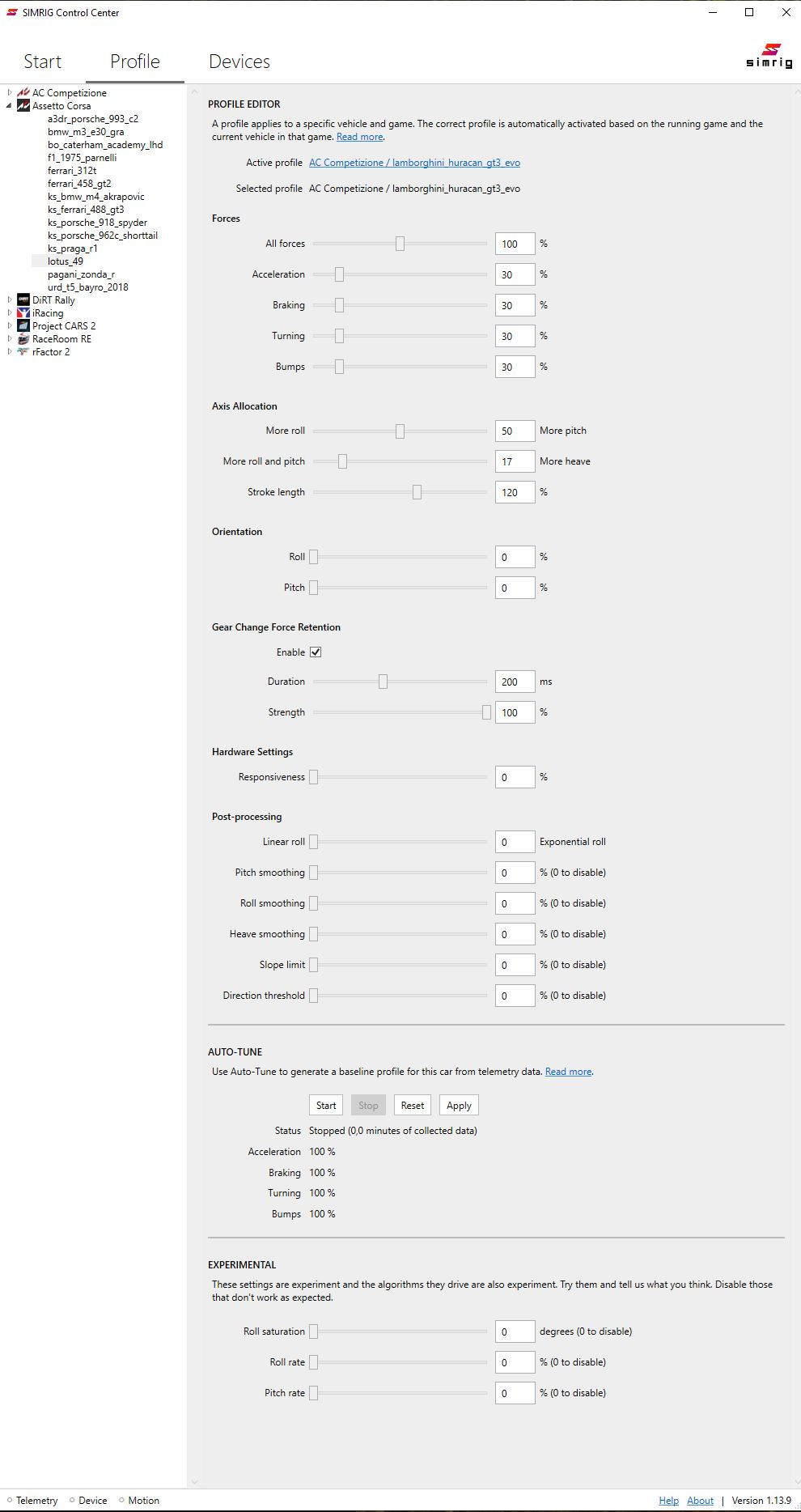

All important settings for fine tuning can be made here. I'm still testing, but it's working pretty well. First you should let the autotuning work and then adjust your individual preferences. Simrig wants to add a database of users to his webpage. Then you can download and install profiles. Each car has to be adjusted individually so that you can feel the movements as realistically as possible. So far I have always driven the cars on the Nordschleife two laps and then had useful results. But the autotuning only sets the 3 free degrees, all other settings have to be adjusted by hand, this is relatively time-consuming! On the picture you can see the basic setting.

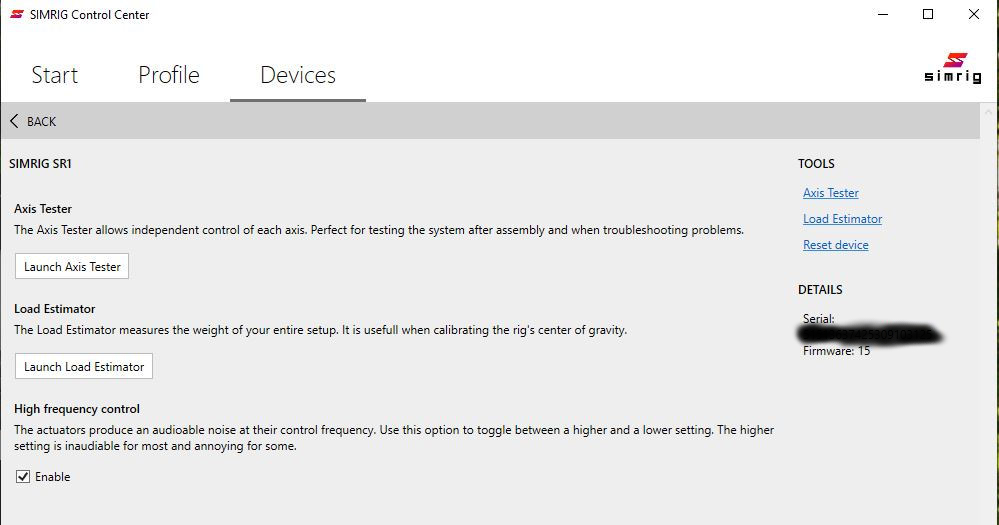

The software offers two more things. You can get the approximate weight of your rig, but that doesn't work so well yet. However, the software determines the load distribution quite well and thus the actuators can be positioned correctly.

If you are bored, the Motion Rig can be moved freely in all directions.

In summary, I can say a good product!

Pro:

1. relatively cheap

2. Plug and Play

3. low weight

4. few cables and only one control unit

5. software with many functions (should be updated regularly)

6. no trouble with components

7. good performance

8. very good support by company (I had an answer to email inquiries on the same day with good results)

9. fast delivery

Cons:

1. slight clacking of the actuators

2. fan from power supply very loud

3. only suitable for lighter rigs and persons

Here's another video:

Wow, the first laps of Raceroom with the BMW DTM 2016 on the Nordschleife blew me away! Everything went very well, and my previous concerns, like no power, little distance, weaker electric motors, worm gears, rack and pinion gears were no longer there. Actually I had considered the SFX-100 system or the PT actuators, maybe the Frex as well. But the effort and the additional equipment and probable trouble with some non-functioning parts kept me from going that other way.

After these two weeks I don't regret the purchase.

Unfortunately I don't have the possibility to test the other systems, but I think that you can make comparisons on Youtube and see how powerful the Simrig system is.

Well, one limitation should be mentioned, because the actuators are designed with 50kg each, that means, the Monster Rigs, which were built for heavy people and actually not existing loads, can not be operated with the SR-1. My rig weighed without the SR-1 system with the Fanatac Podium DD2, the CSP V3, Sparco R100 seat and the aluminum profiles exaggerated 60 kg. With the SR-1 system approx. 75kg. I am slim and when I have eaten the Christmas goose I weigh 75kg. So 150Kg are to be mastered and the SR-1 system manages that without complaining.

The 100mm/s give a comparable angular speed to the other systems due to the close positioning of the actuators. I would also describe the response behavior of the actuators as brutal. The volume is audible but not very disturbing. What's a bit annoying is the mechanical play, which causes a clear crackling when counter-movements occur. With the supplied software, however, a smoother response can be set and the clattering disappears almost completely.

Unfortunately, the cooling of the power supply is a complete construction error. A three centimeter fan with approx. 5000 rpm screams the heat out of the case. It starts every 10min.

Here you see the actuator. Almost the entire part was produced in 3D printing. The motor drives the rack in the actuator with a worm gear.

The assembly is relatively simple. Two 20x20 aluminum profiles are screwed under the rig to which the actuators are attached. The side brackets of the actuators are specially made for different sizes.

A single control unit supplies the actuators with the required voltage and current. This is very practical as you don't need an additional rack for control units.

In total my rig weighs about 75kg now, so people with up to 100kg live weight could have fun.

I can screw on these rollers quickly and the relatively low weight of the rig keeps it mobile.

The power supply unit stands out due to its enormous noise development. Maybe I'll put on a hand there and install a bigger and quieter fan. But I would have to cut a hole in the case cover. But, what the hell!

Start screen of the software.

All important settings for fine tuning can be made here. I'm still testing, but it's working pretty well. First you should let the autotuning work and then adjust your individual preferences. Simrig wants to add a database of users to his webpage. Then you can download and install profiles. Each car has to be adjusted individually so that you can feel the movements as realistically as possible. So far I have always driven the cars on the Nordschleife two laps and then had useful results. But the autotuning only sets the 3 free degrees, all other settings have to be adjusted by hand, this is relatively time-consuming! On the picture you can see the basic setting.

The software offers two more things. You can get the approximate weight of your rig, but that doesn't work so well yet. However, the software determines the load distribution quite well and thus the actuators can be positioned correctly.

If you are bored, the Motion Rig can be moved freely in all directions.

In summary, I can say a good product!

Pro:

1. relatively cheap

2. Plug and Play

3. low weight

4. few cables and only one control unit

5. software with many functions (should be updated regularly)

6. no trouble with components

7. good performance

8. very good support by company (I had an answer to email inquiries on the same day with good results)

9. fast delivery

Cons:

1. slight clacking of the actuators

2. fan from power supply very loud

3. only suitable for lighter rigs and persons

Here's another video: