This thread is for anyone who is thinking of installing 6 transducers to their sim rig, either from scratch or as an upgrade.

My existing setup was two Buttkickers Advances bolted to a 80/20 rig, one attached under the pedals and one under the seat, both powered by a single Behringer iNuke 1000DSP. For anyone interested in my journey to that point, see the thread Getting into Tactile Immersion - Help Please?

Recently, an opportunity arose to purchase 2x Buttkicker Advances; 1x Buttkicker LFE; 1x Clark TST239; 2x Behringer iNuke 3000DSP; & an assortment of cables.

But before starting, firstly my thanks to @Mr Latte, without whose expertise and willingness to share that expertise none of this would be possible, and thanks to @signman for the opportunity, and to whom I wish all the best in his future ventures.

But before starting, firstly my thanks to @Mr Latte, without whose expertise and willingness to share that expertise none of this would be possible, and thanks to @signman for the opportunity, and to whom I wish all the best in his future ventures.

The plan is:

My existing setup had the seat, pedals and Buttkickers isolated from the 80/20 rig using two H shaped 5mm mild steel plates. I wanted to continue this arrangement for (hopefully) best results.

For the seat arrangement I sourced two new 5mm aluminium plates for the BK Advances either side of the seat.

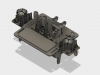

I bolted together the central H plate, two new outer aluminium plates and two seat brackets to create a complete platform to which to attach the Buttkickers and seat.

BKA either side, LFE central underneath.

The seat arrangement bolted to the rig. The 4 isolators results in the seat/Buttkicker section and 80/20 rig being separated from one another. Note a homemade rubber washers at the top of the bolt holding the plate to the 80/20 profile to help reduce the vibration travelling to the rig. On initial testing this is all working quite well.

The pedal area has been more problematic.

The H shape plate under the pedals have been cut in half to create two T shape plates onto which to bolt each BK Advance. This is to reduce the signal from the left travelling to the right, and vice versa.

Initially, I bolted the pedal section to the 80/20 profile via 4 isolators, similar to the photo below.

This should again isolate the pedal section from the 80/20 rig. However, on initial testing I was getting very little vibration in the pedal area, and if I whacked up the gain I would get excessive piston pang.

My theory is that the brackets which hold the Heusinkveld Pro pedal aluminium baseplate are not rigid enough to hold the cantilevered steel plates and Buttkickers below, sitting purely on a rather spongy isolator.

This results in too much movement and flex when the Buttkickers vibrate, reducing significantly the amount of vibration that actually makes its way into the pedals and the base plate.

Therefore, I have changed it so that for now I have bolted the steel plates directly bolted to the 80/20 rig, with no isolation.

Initial testing shows that this gives better vibration. Although there is a bit more bleed of the vibration into the rig, it is not too bad, and certainly not as bad as the piston pang I was getting before. But this is a temporary solution and I will have to revisit this area later.

Currently, the whole setup looks like this.

The TST239 is on the back burner (and remains in its box) until I get the above sorted and work out how best to attach the last transducer. So okay, yes, at the moment it is an upgrade to 5 transducers!

Future episodes include, "Initial Testing" and "Adding the 6th transducer."

Any comments, suggestions or questions will be gratefully received.

My existing setup was two Buttkickers Advances bolted to a 80/20 rig, one attached under the pedals and one under the seat, both powered by a single Behringer iNuke 1000DSP. For anyone interested in my journey to that point, see the thread Getting into Tactile Immersion - Help Please?

Recently, an opportunity arose to purchase 2x Buttkicker Advances; 1x Buttkicker LFE; 1x Clark TST239; 2x Behringer iNuke 3000DSP; & an assortment of cables.

The plan is:

- Two Buttkicker Advances one either side of the seat, in 'Chassis' mode;

- Two Buttkicker Advances, one to the left and one to the right underneath the pedals, in 'Chassis' mode;

- One Buttkicker LFE central under the seat in 'Dual Role' mode.

- One TST239 attached somewhere for the seat, to work with the LFE in 'Dual Role.'

My existing setup had the seat, pedals and Buttkickers isolated from the 80/20 rig using two H shaped 5mm mild steel plates. I wanted to continue this arrangement for (hopefully) best results.

For the seat arrangement I sourced two new 5mm aluminium plates for the BK Advances either side of the seat.

I bolted together the central H plate, two new outer aluminium plates and two seat brackets to create a complete platform to which to attach the Buttkickers and seat.

BKA either side, LFE central underneath.

The seat arrangement bolted to the rig. The 4 isolators results in the seat/Buttkicker section and 80/20 rig being separated from one another. Note a homemade rubber washers at the top of the bolt holding the plate to the 80/20 profile to help reduce the vibration travelling to the rig. On initial testing this is all working quite well.

The pedal area has been more problematic.

The H shape plate under the pedals have been cut in half to create two T shape plates onto which to bolt each BK Advance. This is to reduce the signal from the left travelling to the right, and vice versa.

Initially, I bolted the pedal section to the 80/20 profile via 4 isolators, similar to the photo below.

This should again isolate the pedal section from the 80/20 rig. However, on initial testing I was getting very little vibration in the pedal area, and if I whacked up the gain I would get excessive piston pang.

My theory is that the brackets which hold the Heusinkveld Pro pedal aluminium baseplate are not rigid enough to hold the cantilevered steel plates and Buttkickers below, sitting purely on a rather spongy isolator.

This results in too much movement and flex when the Buttkickers vibrate, reducing significantly the amount of vibration that actually makes its way into the pedals and the base plate.

Therefore, I have changed it so that for now I have bolted the steel plates directly bolted to the 80/20 rig, with no isolation.

Initial testing shows that this gives better vibration. Although there is a bit more bleed of the vibration into the rig, it is not too bad, and certainly not as bad as the piston pang I was getting before. But this is a temporary solution and I will have to revisit this area later.

Currently, the whole setup looks like this.

The TST239 is on the back burner (and remains in its box) until I get the above sorted and work out how best to attach the last transducer. So okay, yes, at the moment it is an upgrade to 5 transducers!

Future episodes include, "Initial Testing" and "Adding the 6th transducer."

Any comments, suggestions or questions will be gratefully received.