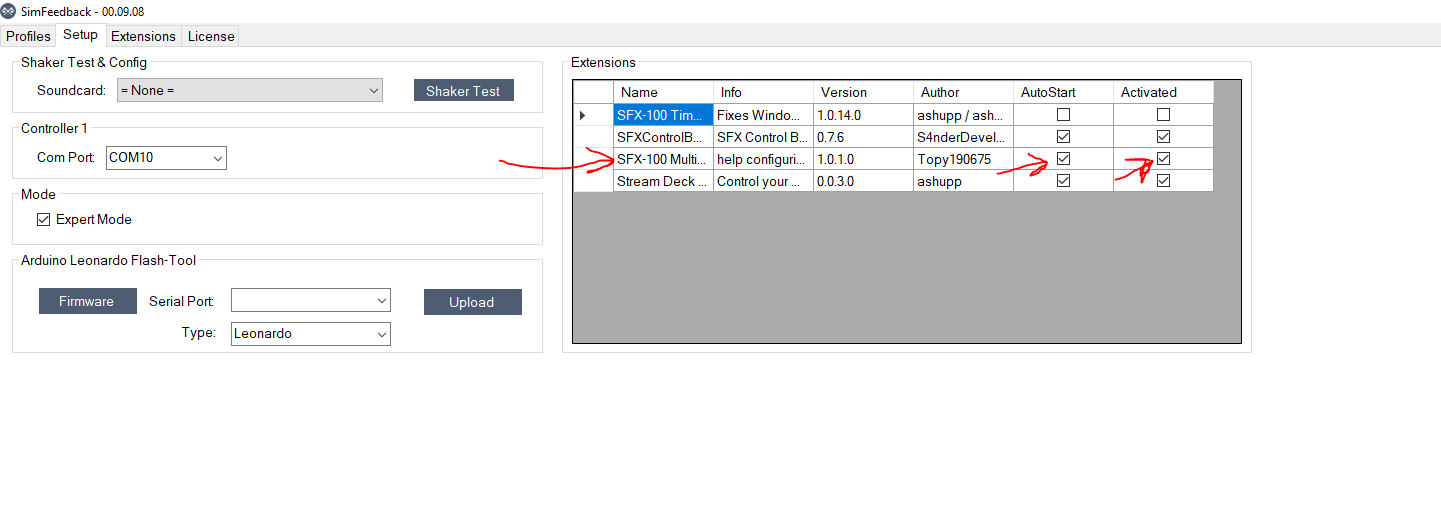

@Andy J I just installed the Mcsetupctrl extension. For me it works perfectly. Just unzip the folder into the "extension" folder in the Simfeedback main directory. Then activate the plugin (see screenshot). Make a restart of Simfeedback and then you should see it in the "Extension" tab (see below).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hoernle's Belt Tensioner - Detailed Build Instructions

- Thread starter Hoernle

- Start date

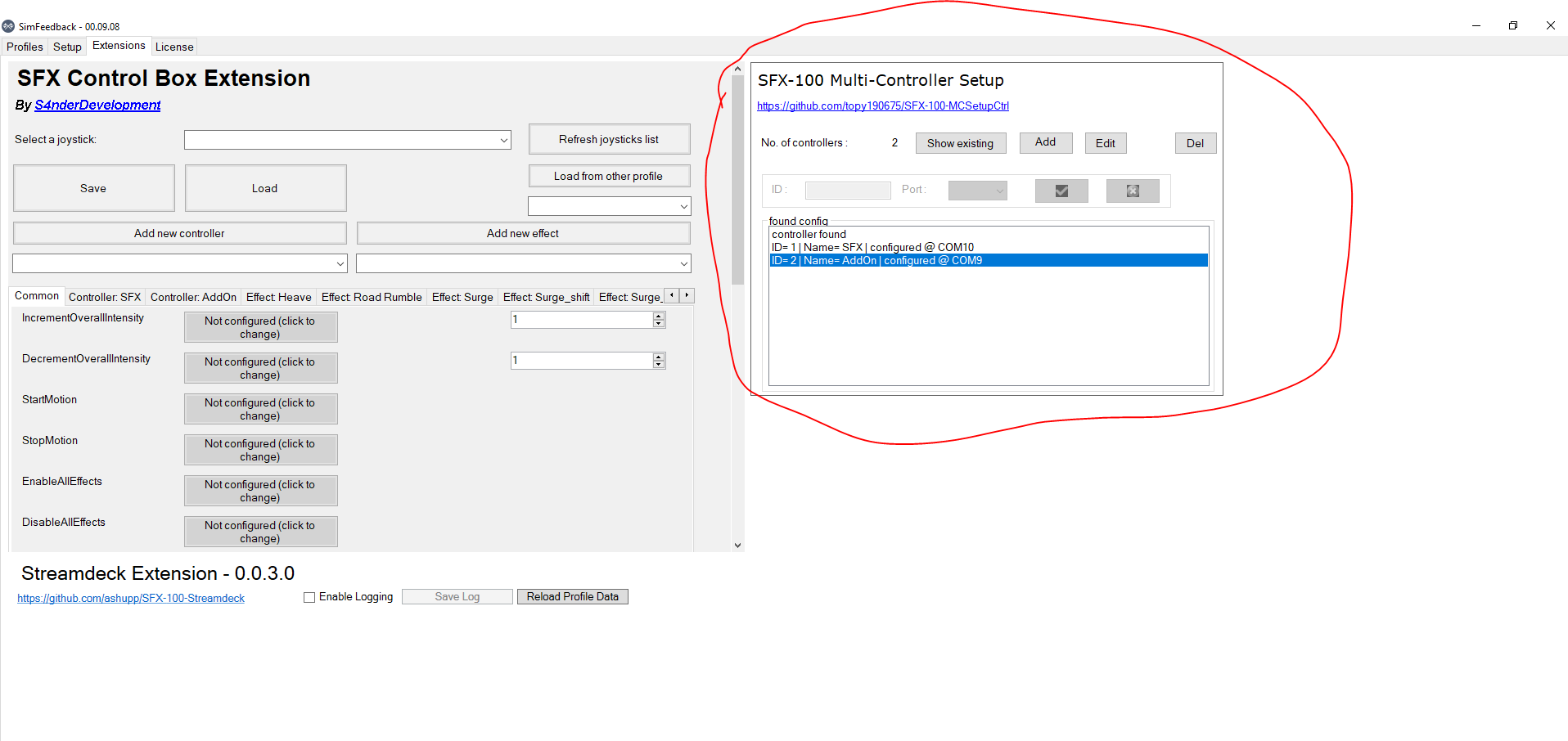

@Andy J fantastic  . The plugin is super simple. Just click "add" to generate another controller. Each arduino needs one controller. Afterwards, just assign the correct COM port. In the device manager you will see which COM port belongs to your second arduino. Obviously, don't forget to click the green check mark to save. Probably you have to do a restart to see the second controller in the effect menu.

. The plugin is super simple. Just click "add" to generate another controller. Each arduino needs one controller. Afterwards, just assign the correct COM port. In the device manager you will see which COM port belongs to your second arduino. Obviously, don't forget to click the green check mark to save. Probably you have to do a restart to see the second controller in the effect menu.

So I have got the second controller connect, and the servo motor I am using starts up just like the main ones on the SFX100, but I cannot get any movement out if during a simulation. I am NOT using the same servo and controller as the SFX100, but a NEMA 32 and servo controller (open loop) - perhaps this is the issue ? but I would have thought that the simfeed back software is pushing out PWM signal so either should work as there appears to be no feedback loop to simfeedback judging by the wiring (only pulse/step , direction and enable).

The fact that the NEMA servo goes to the mid position using controller 2 when starting up had me hopeful - but now I am not sure .....

The fact that the NEMA servo goes to the mid position using controller 2 when starting up had me hopeful - but now I am not sure .....

NEMA is a dimension specification for flange size, not a servo brand...

Is it NEMA32 flange? NEMA34?

Is it NEMA32 flange? NEMA34?

Hi everybody, I'm in the process of building the belt tensioner according to the very good and detailed instructions found in this thread.

Atm I'm on hold because one of the bearings (the small one) I got from AliExpress looks like being out of spec and the precision shaft doesn't fit in it. So I'm waiting for a new one, that should arrive next week. But I'm not writing here to complain about that but to ask you about the other bearing (the big one, that goes on the motor shaft), that, because of the guide on the motor shaft itself (see attached pic), can be slotted in for just 3-4mm making even difficult to tighten it without it tilting on a side. I finally managed to fix it straight, but, I was wondering if that is normal and acceptable.

I guess the parts I got are the right ones, having sourced the motor directly from ntl-bearing.com (the email given in the part list) and being all the bearings I've seen (on AliExpress, Amazon or the site where I purchased the replacement small one) without a slot to slide that guide in.

The pics in the instructions don't reveal if the motor used had that guide and it's hard to judge from them how deep the shaft goes into the bearing, so I was wandering if I'm actually doing it right.

Thanks in advance for your support.

Atm I'm on hold because one of the bearings (the small one) I got from AliExpress looks like being out of spec and the precision shaft doesn't fit in it. So I'm waiting for a new one, that should arrive next week. But I'm not writing here to complain about that but to ask you about the other bearing (the big one, that goes on the motor shaft), that, because of the guide on the motor shaft itself (see attached pic), can be slotted in for just 3-4mm making even difficult to tighten it without it tilting on a side. I finally managed to fix it straight, but, I was wondering if that is normal and acceptable.

I guess the parts I got are the right ones, having sourced the motor directly from ntl-bearing.com (the email given in the part list) and being all the bearings I've seen (on AliExpress, Amazon or the site where I purchased the replacement small one) without a slot to slide that guide in.

The pics in the instructions don't reveal if the motor used had that guide and it's hard to judge from them how deep the shaft goes into the bearing, so I was wandering if I'm actually doing it right.

Thanks in advance for your support.

Latest News

-

2024 Formula One Emilia Romagna Grand PrixAfter a somewhat surprisingly intense Miami Grand Prix, Formula One returns to Imola for the...

- Connor Minniss

- Updated:

- 3 min read

-

BMW M4 GT4 To Join RaceRoom GridsAfter the recent announcement of three BMW race cars coming to the sim, RaceRoom unveiled the...

- Yannik Haustein

- Updated:

- 2 min read

-

WATCH: Our Guide To Nordschleife Pronounciation ExcellenceThe Nürburgring-Nordschleife is hard to drive - and its sectors are also hard to pronounce for...

- Yannik Haustein

- Updated:

- 1 min read

-

Guide: How To Negotiate Traffic in Endurance RacesWith the Nürburgring 24 Hours iRacing Special Event taking place this weekend, traffic...

- Luca Munro

- Updated:

- 5 min read

-

Hot Lap Racing Shows Switch GameplayThe first gameplay showcase of Hot Lap Racing is here, showing various captures from the...

- Yannik Haustein

- Updated:

- 2 min read

-

Rennsport Beta Update 1.8.5 Adds Surprise LMDh Car, Rolling StartsThe latest beta release is here: Rennsport update 1.8.5 adds two current endurance prototype...

- Yannik Haustein

- Updated:

- 2 min read

-

Vehicle Software Company Marble Labs Announces Potential FFB Replacement TechForce Feedback is essential to enjoying sim racing. US-based vehicle software company Marble...

- Yannik Haustein

- Updated:

- 3 min read