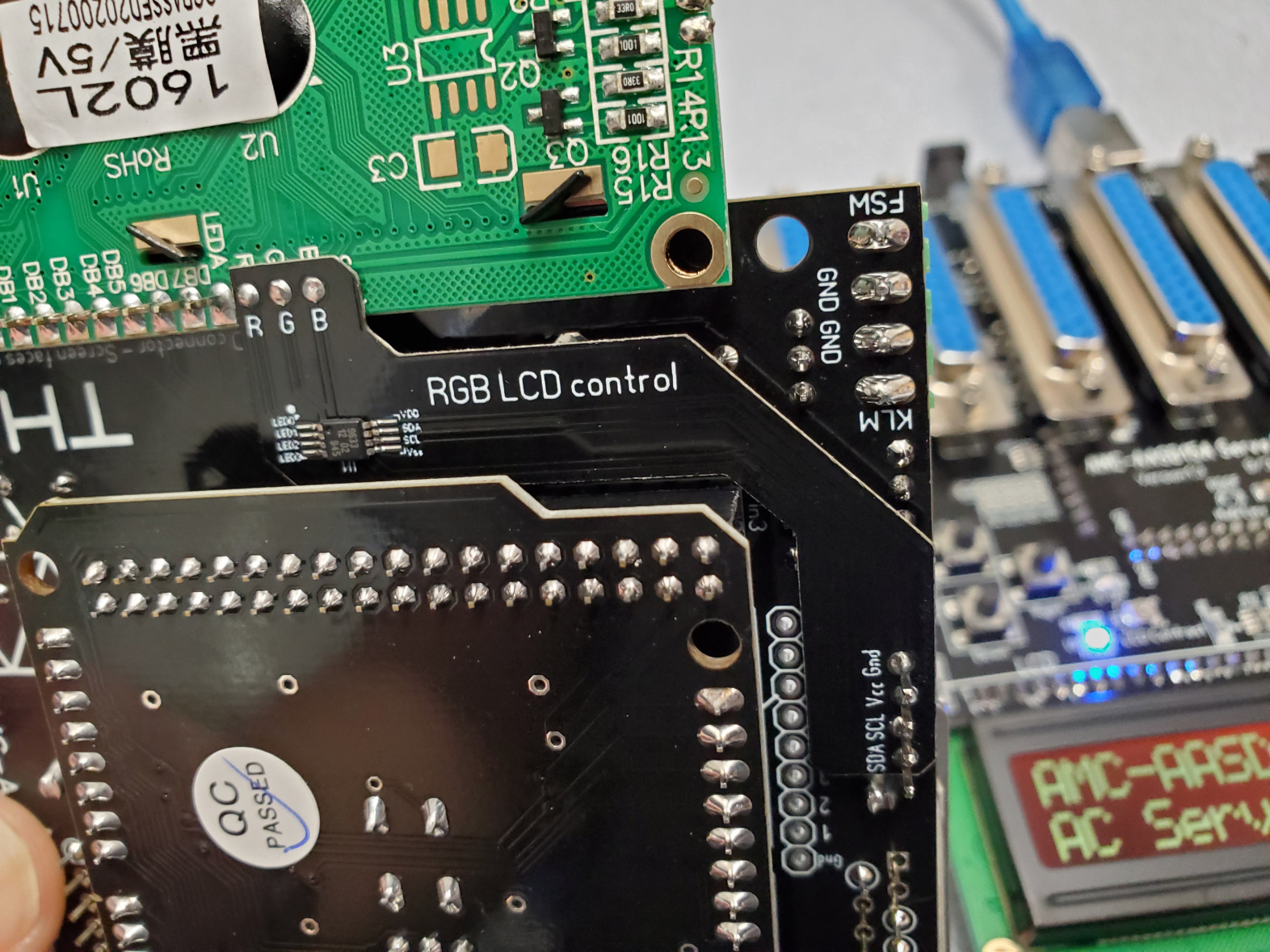

The AMC-AASD15A is now available with optional RGB LCD display...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Authorised Vendor Thanos AMC-AASD15A 6axis Servo Motion Controller

- Thread starter Tronicgr_6DOF

- Start date

I see many guys who have installed a power conditioner for their servodrives.

I`m really not into electronics and glad, when i managed to wire up my servodrives.

So to speak clearly, i never heard of a power conditioner. What he does ? Do i really need one and why ? And, what is the difference of plugging the electronics into a power conditioner vs. plugging the servodrives into a normal extensioncable ?

The power conditioner is useful to prevent some EMI/RFI noise propagate back to power lines and affect other systems in same line, like your PC, VR headset, even speakers... there are inexpensive EMI testers to help you locate the sources of EMI...

I have a Thanos question... I'm to the stage of programming my AASD drives for my SFX variant I'm building. Right now I'm doing 3dof but am designing around/planning to later add surge/tl. I have your AASD controller but have slightly different motors than the standard selection. My platform uses 1610 ballscrews, has 150mm travel and uses 80mm extrusions. I was loosely following Mavric's build but used my own files for all but the sliders. His build calls for the 4nm version of the motor but I wanted to keep my system able to run on normal 15a/110v circuit (I'm in the US).

As such I opted for the 90ST MO3520 versions. They use the same drive but are 2000rpm/3.5nm and on paper the most efficient of the lot. 2000rpm/10mm screw is 333mm/s, plenty fast and the lower rpm should be less noisy. Now I need to set the parameters on the drives and am not sure which ones I have to change to accommodate my motor selection.

I know I need to change/add

pn51 = 2000 (rpm)

Pn083 = 100 (voltage alarm to be able to run on 110v)

Are there any other parameters I need to alter from the recommended settings below from your manual?

Pn8 = 300

Pn9 = -300

Pn51 = 3000 (should be 2000 for MO3520)

Pn98 = 20 -Pulse Multiplier (electronics gear)

Pn109 = 1 -smoothing, 1=fixed smoothing, 2=s-Shaped smoothing

Pn110 = 30 -Smoothing Filter Time

Pn113 = 20 -Feedforward %

Pn114 = 10 -Feedforward Filter Time (ms)

Pn115 = 100 -Gain %

---Extra parameters needed---

Pn24 = 100

Pn52 = 1

Pn60 = 2

Pn61 = 6

Here's a data sheet for the 90st's

Thanks for any help you can provide, pretty excited to be closing in on a rig of my own after coming so close so many times over the last decade+... I remember watching youtube vids of your first pvc 2dof rigs when they were originally posted!

As such I opted for the 90ST MO3520 versions. They use the same drive but are 2000rpm/3.5nm and on paper the most efficient of the lot. 2000rpm/10mm screw is 333mm/s, plenty fast and the lower rpm should be less noisy. Now I need to set the parameters on the drives and am not sure which ones I have to change to accommodate my motor selection.

I know I need to change/add

pn51 = 2000 (rpm)

Pn083 = 100 (voltage alarm to be able to run on 110v)

Are there any other parameters I need to alter from the recommended settings below from your manual?

Pn8 = 300

Pn9 = -300

Pn51 = 3000 (should be 2000 for MO3520)

Pn98 = 20 -Pulse Multiplier (electronics gear)

Pn109 = 1 -smoothing, 1=fixed smoothing, 2=s-Shaped smoothing

Pn110 = 30 -Smoothing Filter Time

Pn113 = 20 -Feedforward %

Pn114 = 10 -Feedforward Filter Time (ms)

Pn115 = 100 -Gain %

---Extra parameters needed---

Pn24 = 100

Pn52 = 1

Pn60 = 2

Pn61 = 6

Here's a data sheet for the 90st's

Thanks for any help you can provide, pretty excited to be closing in on a rig of my own after coming so close so many times over the last decade+... I remember watching youtube vids of your first pvc 2dof rigs when they were originally posted!

I have a Thanos question... I'm to the stage of programming my AASD drives for my SFX variant I'm building. Right now I'm doing 3dof but am designing around/planning to later add surge/tl. I have your AASD controller but have slightly different motors than the standard selection. My platform uses 1610 ballscrews, has 150mm travel and uses 80mm extrusions. I was loosely following Mavric's build but used my own files for all but the sliders. His build calls for the 4nm version of the motor but I wanted to keep my system able to run on normal 15a/110v circuit (I'm in the US).

As such I opted for the 90ST MO3520 versions. They use the same drive but are 2000rpm/3.5nm and on paper the most efficient of the lot. 2000rpm/10mm screw is 333mm/s, plenty fast and the lower rpm should be less noisy. Now I need to set the parameters on the drives and am not sure which ones I have to change to accommodate my motor selection.

I know I need to change/add

pn51 = 2000 (rpm)

Pn083 = 100 (voltage alarm to be able to run on 110v)

Are there any other parameters I need to alter from the recommended settings below from your manual?

Pn8 = 300

Pn9 = -300

Pn51 = 3000 (should be 2000 for MO3520)

Pn98 = 20 -Pulse Multiplier (electronics gear)

Pn109 = 1 -smoothing, 1=fixed smoothing, 2=s-Shaped smoothing

Pn110 = 30 -Smoothing Filter Time

Pn113 = 20 -Feedforward %

Pn114 = 10 -Feedforward Filter Time (ms)

Pn115 = 100 -Gain %

---Extra parameters needed---

Pn24 = 100

Pn52 = 1

Pn60 = 2

Pn61 = 6

Here's a data sheet for the 90st's

Thanks for any help you can provide, pretty excited to be closing in on a rig of my own after coming so close so many times over the last decade+... I remember watching youtube vids of your first pvc 2dof rigs when they were originally posted!

Hi, all parameters should be same except Max motor RPM, which in your case should be 2000.

Just don't forget to set proper leadscrew to 10mm/s and stroke to 150mm and you should be fine.

Thanks

Thanos

What values should we be looking for (or not looking for) with the EMF meter? What is consider too high?

Usually the regulations prohibit devices to emit detectable EMI/RFI emissions beyond a distance of 10 feet. And that is true from what you can see in the video. Nothing is detected 3 feet away from the servo and its cabling. But on a motion rig you also install on it other devices too close to these sources and it can affect them. The only way is good shielding and eliminating ground loops.

Thanks

Thanos

Hi, all parameters should be same except Max motor RPM, which in your case should be 2000.

Just don't forget to set proper leadscrew to 10mm/s and stroke to 150mm and you should be fine.

Thanks

Thanos

Awesome, thanks. Got it setup and the motor hooked up and I'm not sure if this is normal behavior but with everything plugged in the motor just keeps rotating at like 50rpm and doesn't respond to position button commands. All the sockets on the controller behave the same. There is a 'C' on the display which I think means it's trying to calibrate itself but since it's not on an actuator it doesn't hit a stop.

I tried looking around and didn't find the answer but is there a way to bypass the calibration cycle? I just want to be able to jog the motors using the buttons to ensure everything is dialed before proceeding or am I missing something?

Awesome, thanks. Got it setup and the motor hooked up and I'm not sure if this is normal behavior but with everything plugged in the motor just keeps rotating at like 50rpm and doesn't respond to position button commands. All the sockets on the controller behave the same. There is a 'C' on the display which I think means it's trying to calibrate itself but since it's not on an actuator it doesn't hit a stop.

I tried looking around and didn't find the answer but is there a way to bypass the calibration cycle? I just want to be able to jog the motors using the buttons to ensure everything is dialed before proceeding or am I missing something?

The AMC-AASD15A expects the motor to stop against hard stop (end of travel of actuator)

The torque to stop the motor while calibrates is not too much, you can even use carefully your hand or something to hold and stop the shaft... see on this video at 0:45

With your controller do I need to leave a safety margin and limit travel? I know some software says to limit to say 95% .

You don't need to limit the safety margin. Except if you load the actuator too much and might have inertia. This is the case when using TL or Surge actuators, where occasionally you may hear a small "tok" when the actuator is near travel limits. But if you enable the spike filter in the controller, it will automatically prevent the actuators running full speed on the end travels of the actuators, if accidentally crash against against a wall on the track.

Awesome, thanks. Got it setup and the motor hooked up and I'm not sure if this is normal behavior but with everything plugged in the motor just keeps rotating at like 50rpm and doesn't respond to position button commands. All the sockets on the controller behave the same. There is a 'C' on the display which I think means it's trying to calibrate itself but since it's not on an actuator it doesn't hit a stop.

I tried looking around and didn't find the answer but is there a way to bypass the calibration cycle? I just want to be able to jog the motors using the buttons to ensure everything is dialed before proceeding or am I missing something?

Here is a better video that explains it:

Thanks Thanos, I got it sorted after watching you stop the motor on the last vid but didn't realize I could just jump those pins, very useful. Got all my motors/drives tested and had a worrisome moment where one started throwing Al codes and the motor was getting hot. After swapping around components I was able to isolate it to the power cable being miswired, W and V are swapped in one of the screw connectors. The motor was still getting hot which led me to discover one of the drives had weird programming so I went through line by line and reset them all to default or the spec'd parameters for the platform and it stopped getting hot.

To that end, is there an easy way to reset all the parameters to default? I only reset them on one unit but for peace of mind I think I want to reset them all and reprogram them again to be sure. I've looked around for the easy reset solution but haven't found one yet

To that end, is there an easy way to reset all the parameters to default? I only reset them on one unit but for peace of mind I think I want to reset them all and reprogram them again to be sure. I've looked around for the easy reset solution but haven't found one yet

Thanks Thanos, I got it sorted after watching you stop the motor on the last vid but didn't realize I could just jump those pins, very useful. Got all my motors/drives tested and had a worrisome moment where one started throwing Al codes and the motor was getting hot. After swapping around components I was able to isolate it to the power cable being miswired, W and V are swapped in one of the screw connectors. The motor was still getting hot which led me to discover one of the drives had weird programming so I went through line by line and reset them all to default or the spec'd parameters for the platform and it stopped getting hot.

To that end, is there an easy way to reset all the parameters to default? I only reset them on one unit but for peace of mind I think I want to reset them all and reprogram them again to be sure. I've looked around for the easy reset solution but haven't found one yet

To reset Factory AASD-15A parameters

Select Fn004

No need to enter a value. Just press/hold the Set button and it displays Pni n then press/hold Set again.. displays go... done... Remove power and plug back in..

Have discord channels been removed recently? Just starting my discovery on all of this and joined the discord to see the traction and surge actuator discussion there...couldn’t find it?

Nope... still there....

Attachments

Hi

I next few days i will put together my first DIY sfx100. I have: AMC-AASD15A

I am looking short and simple answer:

What to choose:

I want to add also in next 6 months tactile feedback from 4 shakers with amplifier.

Thanks for help!

I next few days i will put together my first DIY sfx100. I have: AMC-AASD15A

I am looking short and simple answer:

What to choose:

- FlyPT Mover

- Simtools

- something else

I want to add also in next 6 months tactile feedback from 4 shakers with amplifier.

Thanks for help!

FlyPT is free, you can try that first.

But if you like broader access to games, Simtools is best.

See instructions for simtools in the manual:

github.com

github.com

Thanks

Thanos

But if you like broader access to games, Simtools is best.

See instructions for simtools in the manual:

AMC-AASD15A-Firmware/AMC-AASD15A_4DOF+TL-Simtools_manual_v2_3.pdf at master · tronicgr/AMC-AASD15A-Firmware

Firmware and design files for AMC-AASD15A servo controller for AASD-15A and compatible drives - AMC-AASD15A-Firmware/AMC-AASD15A_4DOF+TL-Simtools_manual_v2_3.pdf at master · tronicgr/AMC-AASD15A-Fi...

Thanks

Thanos

Updating a few things in the LCD menu to improve the navigation for the users. See in the video what is new:

Latest News

-

OverTake Goes Brickyard: Join Our OT IndyCar 500 (km) In rF2 For FreeIt is race week for the Biggest Spectacle in Racing, so our Racing Club is hosting its own...

- Yannik Haustein

- Updated:

- 2 min read

-

Column: A Sim Racer's Fleeting Visits to Laguna Seca and MonacoIn the past few weeks, I have been lucky enough to travel to two iconic venues in motorsport...

- Angus Martin

- Updated:

- 5 min read

-

When German Formula 3 Went Oval RacingOval racing has never really taken off in Europe, despite CART's attempts in the early 2000s...

- Yannik Haustein

- Updated:

- 4 min read

-

Short Oval Racer's First Time Experience With IndyCarFull contact and rough and ready. That's banger racing. However, IndyCar swiftly taught me that...

- Connor Minniss

- Updated:

- 5 min read

-

Racing Club Schedule: May 19 - 26The Racing Club goes to Monaco this week - multiple times, and throughout the ages! Indy 500...

- Yannik Haustein

- Updated:

- 4 min read

-

Recreating My Motorsport Photos In Sim RacingFrom supertourers, to banger cars - recreating my motorsport photos in my favourite sim racing...

- Connor Minniss

- Updated:

- 5 min read

-

Sponsored Battling With The Pros At Racing Unleashed's All-Star EventOur own René Buttler was invited by Racing Unleashed to battle pro sim racers at their racing...

- Luca Munro

- Updated:

- 8 min read